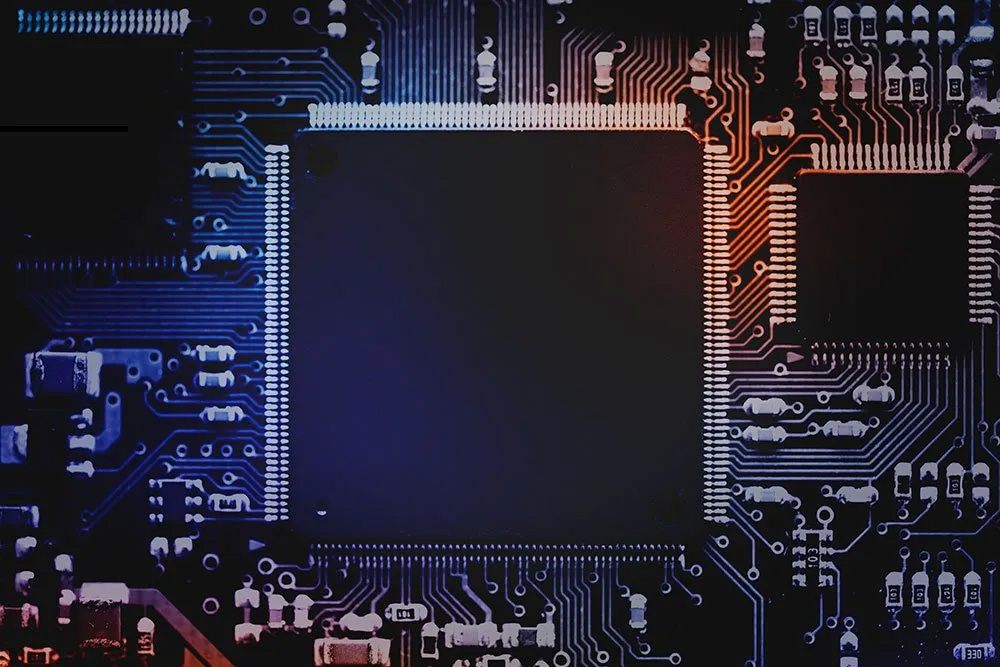

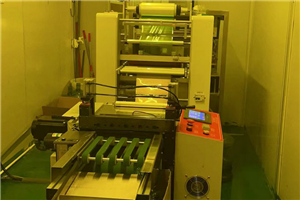

In order to ensure good performance and service life in harsh environments, some design factors need to be considered when manufacturing industrial PCBs. Below are some of the factors listed.

thermal management

When we consider industrial PCB design, we need to take into account heat dissipation factors. To achieve proper heat dissipation, it is necessary to add heat sinks, thermal vents, and convenient layouts.

The material used for the substrate can also affect the thermal management of the PCB. Metal cores are usually used as substrates to provide better thermal performance.

Careful placement of components that generate excessive heat is also a key factor in preventing overheating and managing the overall temperature of the circuit board.

Signal integrity

In order to achieve appropriate signal efficiency on the circuit board, properties such as line width and spacing between components and layers must have appropriate proportions.

Proper wiring must also be done on the circuit board to minimize possible signal loss and crosstalk.

Impedance control is crucial for ensuring the signal integrity of PCBs. It is always recommended to maintain a consistent high-frequency signal impedance to achieve good signal integrity.

By using a continuous ground plane in the PCB, noise and EMI (electromagnetic interference) in the signal can be reduced.

power distribution

Industrial PCBs must have sensitive power and ground layers, which will help them reduce noise and maintain stable voltage levels.

Noise in the power supply can be eliminated by adding decoupling capacitors near the power pins of the integrated chip (IC) in the PCB.

In addition, industrial equipment PCBs are also suitable for high-power input and output devices. This can be solved by increasing sufficient wire width, especially on power lines and PCBs in high current areas where voltage drops are often excessive.

environmental factor

To prevent the circuit board from getting damp, appropriate coatings and protective measures will be added to the PCB. This coating helps prevent moisture from entering the circuit. Epoxy resin is a commonly used coating in industrial equipment PCBs.

Ensure that the materials and components used have high temperature resistance. This is crucial in extremely high temperature environments, and the components used should be able to withstand such harsh conditions.

Electromagnetic interference (EMI)

To prevent electromagnetic interference on the PCB, shielding technology must be implemented at the top of the PCB.

The use of ferrite beads and capacitors as filters in circuits helps prevent potential noise and EMI in circuit boards.

By adopting effective grounding methods for circuit boards, EMI can also be reduced or minimized.

Structure Design

When considering the mechanical factors in designing industrial PCBs, it is important to choose the appropriate thickness to ensure that the manufactured circuit board has appropriate mechanical strength and durability.

The mechanical design of industrial PCB boards must also be able to withstand industrial impacts and vibrations.

Compliant with standards

When designing and manufacturing industrial PCBs, certain industry standards must be met, such as IPC (Printed Circuit Board Association), UL (Underwriters Laboratories), EMC (Electromagnetic Compatibility), and RoHS (Restriction of Hazardous Materials Directive).

Certain safety requirements and appropriate insulation measures must be taken to avoid potential threats and ensure the electrical safety and reliability of the circuit board.