Flexible PCB manufacturers can now design, manufacture, and customize PCBs of various specifications. Although there have been significant changes, flexible circuit boards can be roughly classified into several types based on their number of layers and configuration.

By layer: single-sided, double-sided, and multi-layer flexible PCB

According to the number of layers of flexible printed circuit boards, they can be divided into single-sided, bidirectional, and multi-layer PCBs, each with its own advantages and characteristics. Although the more layers, the more components can be connected, the complexity and overall cost will also increase accordingly. Therefore, engineers at Haibo will carefully study project requirements to find the most suitable type of flexible printed circuit board for the application.

Single sided flexible PCB: With only one conductive layer in a single layer, it is currently the most commonly used flexible printed circuit board. It has excellent electronic and mechanical properties of flexible materials, and is low-cost, so it is widely used in consumer electronics products.

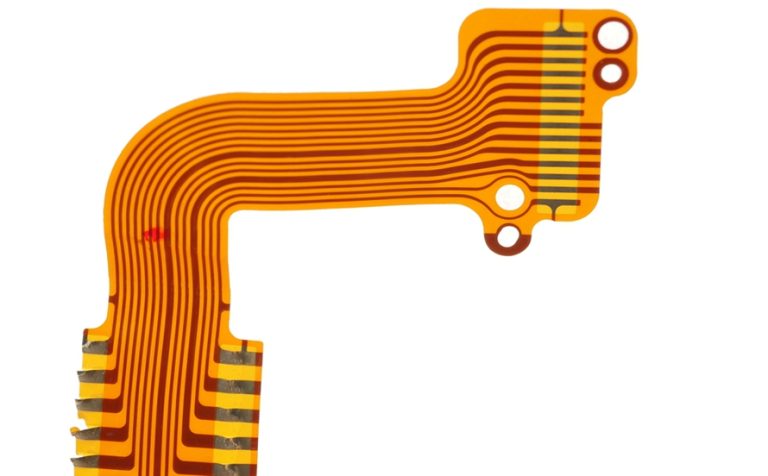

Double sided flexible PCB: A double-layer flexible circuit board has two layers of copper connected by plated through holes, which combines high electronic performance and cost-effectiveness. It is usually used for high-capacity high-tech electronic devices such as laptops, cameras, headphones, etc.

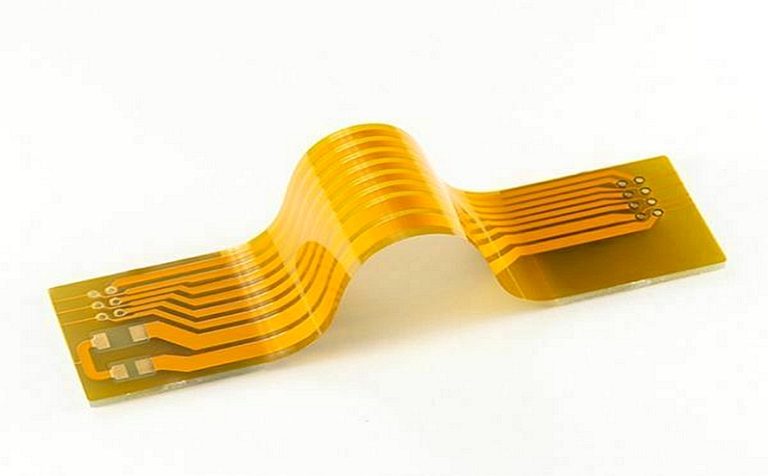

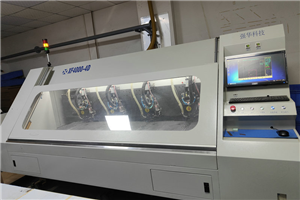

Multi layer flexible PCB: For this highly advanced equipment that requires very limited space or continuous movement, we need to use multi-layer flexible PCB boards, such as for robots, industrial equipment, and medical applications. This flexible PCB has three or more copper layers. But generally speaking, we recommend using four or more copper layers in flexible PCBs, which can affect flexibility.

According to characteristics: standard flexible PCB, rigid flex PCB, and HDI flexible PCB

Similarly, according to the configuration, flexible circuit boards can be divided into standard flexible PCBs, rigid flexible combination PCBs, and HDI flexible PCBs.

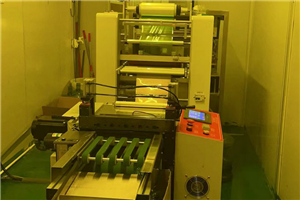

Standard flexible PCB: Standard flexible PCB is the most commonly used flexible circuit board. They are usually made of polyimide and have one or two conductive layers and reinforcing ribs.

Rigid flex PCB: As the name suggests, rigid flex PCB combines the characteristics of both rigid and flexible PCBs. In this type of flexible PCB board, only the required areas of the PCB are made of flexible materials, which helps to connect the rigid parts of the circuit. This reduces costs while allowing the PCB to bend as needed.

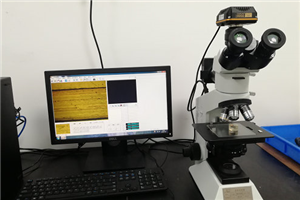

HDI flexible PCB: HDI flexible PCB or high-density interconnect circuit board can be considered as an advanced version of flexible PCB. They have better functionality and performance than ordinary flexible printed circuit boards.