At the beginning of the 20th century, in order to simplify the production of electronic machines, reduce the wiring between electronic components, and lower production costs, research began on using printing instead of wiring to make circuit boards. For 30 years, engineers have been proposing to add metal conductors to insulating substrates for wiring.

Wiring: The interconnection between electronic components is achieved by directly connecting several random wires to form a circuit. But it has been proven that such circuits do have many problems. Contact points are prone to looseness, leading to poor contact, wire damage, and short circuits. Due to such issues, replacement is necessary,

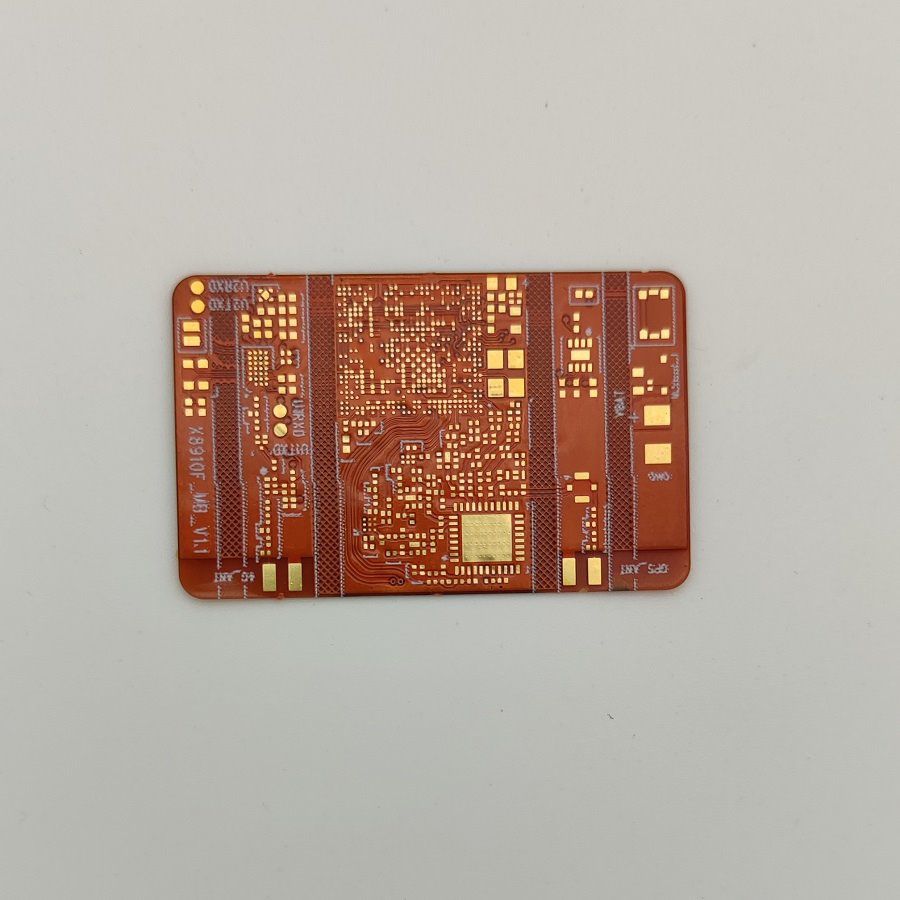

The emergence of PCB (single panel) has effectively solved problems such as messy wiring and poor contact, as electronics has developed rapidly and its own shortcomings have emerged (double-sided board), also known as a substitute for PCB printed circuit board. It is an important electronic component, the support body of electronic components, and the carrier of electronic and electrical connections. Because it is made through electronic printing, it is called a "printed" circuit board. Before the emergence of printed circuit boards, electronic components were directly connected through wires to form a complete circuit.

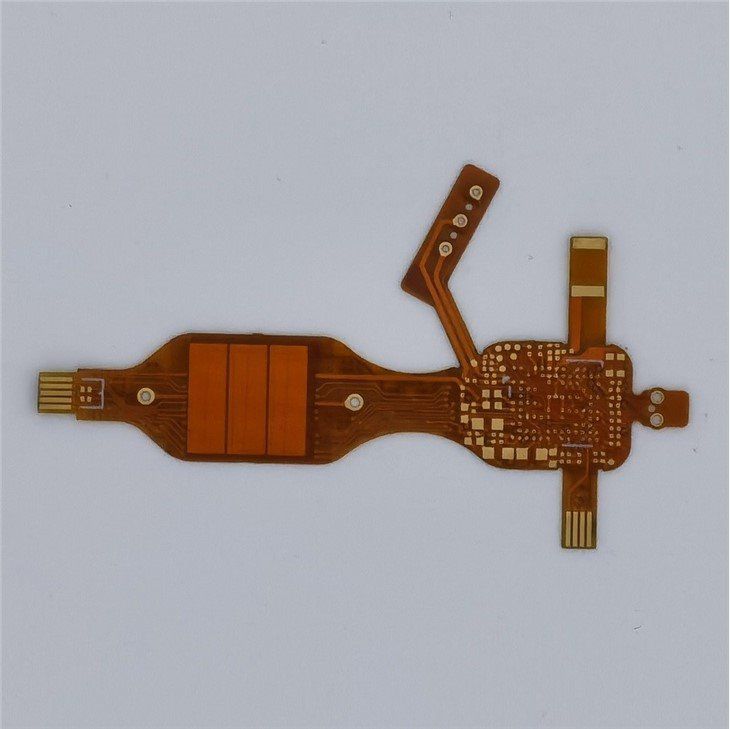

Although it has effectively solved the previous problems, due to its thickness and stiffness characteristics, it can no longer meet the current development trend of electronic products. Therefore, flexible circuit boards should be born, which meet all the advantages of the previous circuit. Short: assembly time, all circuits have been configured. FPC circuit board B. Small size: The volume is smaller than PCB, which can effectively reduce the size of the product. Increase the convenience of portability: lighter in weight than PCB (hard board), reducing the weight of the final product. 4 Thin: The thickness is thinner than PCB, improving flexibility. Strengthening the assembly of three-dimensional space in a limited space.

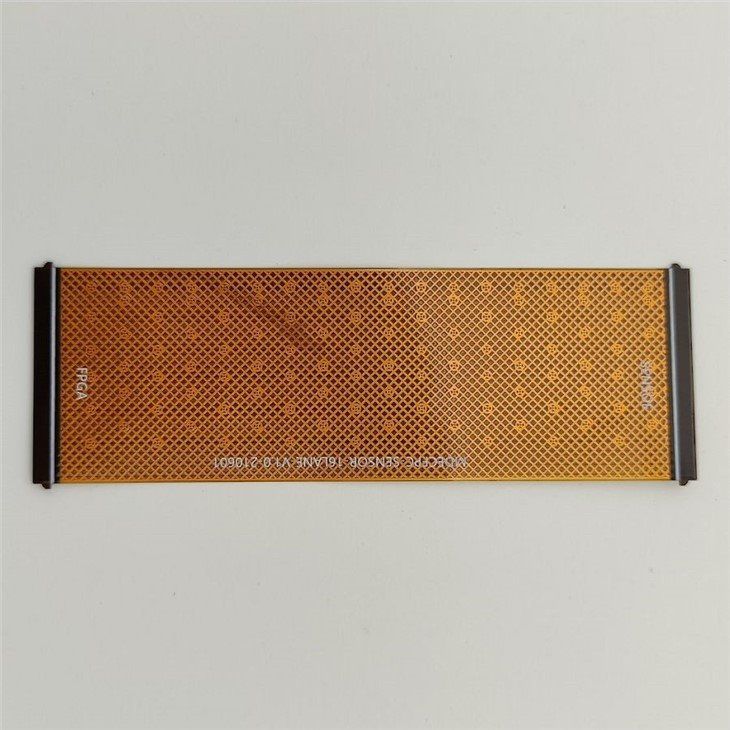

The birth and development of FPC and PCB have given birth to the new product of soft hard combination board. Therefore, the combination of soft and hard circuit boards is the process of combining flexible circuit boards and hard circuit boards through pressing and other processes, according to relevant process requirements, to form a circuit board with FPC characteristics and PCB characteristics.

Therefore, the combination of soft and hard circuit boards is the process of combining flexible circuit boards and hard circuit boards through pressing and other processes, according to relevant process requirements, to form a circuit board with FPC characteristics and PCB characteristics.

Advantages: The combination of soft and hard boards has the characteristics of both FPC and PCB, so it can be used in some products with special requirements. It has both a certain flexible area and a certain rigid area, which saves internal space, reduces the volume of finished products, and greatly helps improve product performance.

Disadvantages: The production process of soft hard composite board is diverse, difficult to produce, low yield rate, and requires a lot of materials and manpower, resulting in higher prices and longer production cycles.