With the continuous development of technology, various fields are becoming intelligent, so FPC circuit boards are widely used in various fields. With the increasing number of FPC manufacturers, there will naturally be some merchants who tamper with the price and quality. So the question is, how to judge the quality of FPC circuit boards?

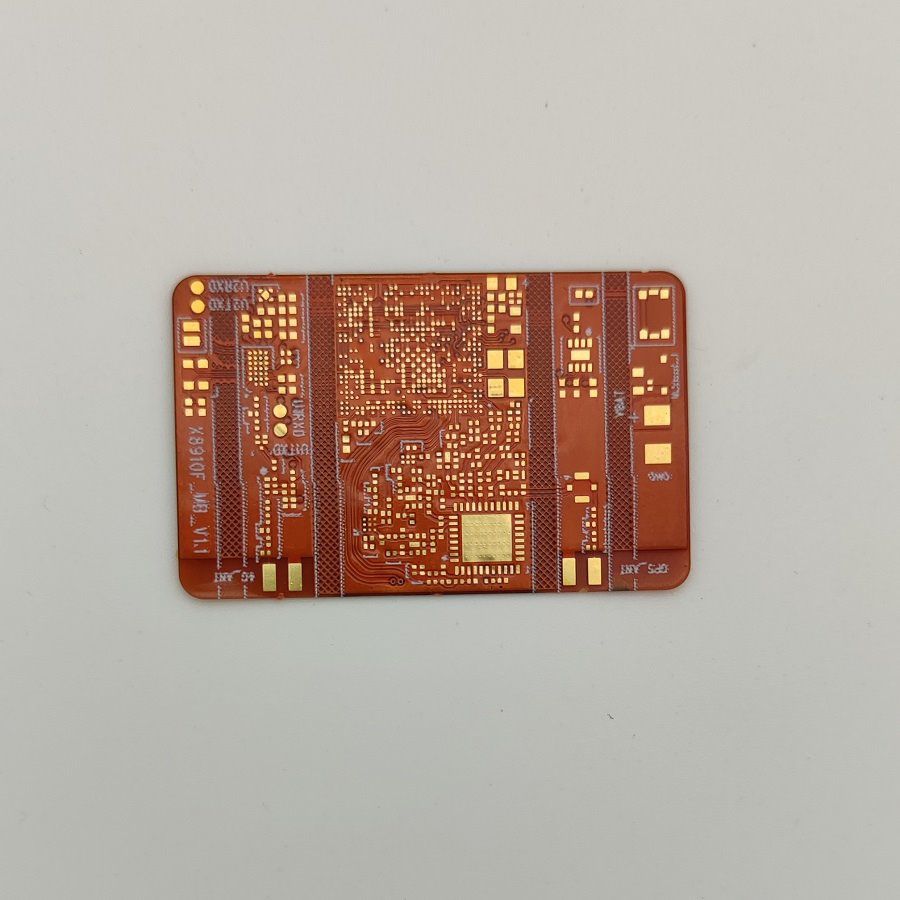

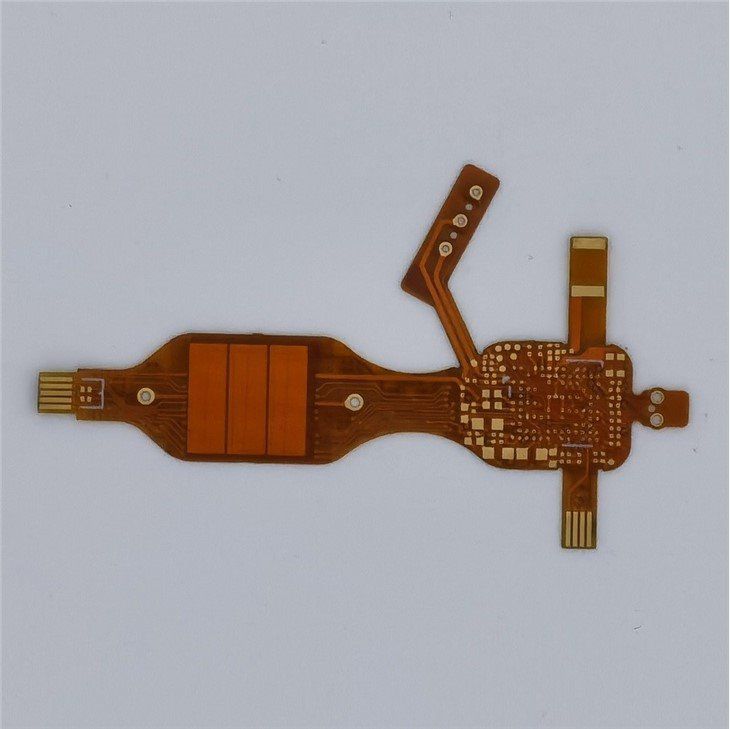

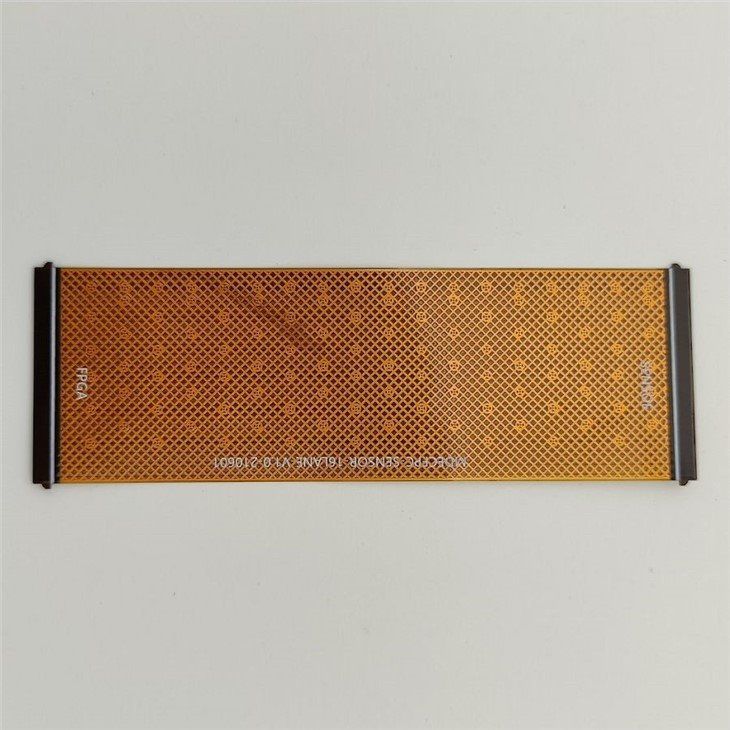

Firstly, distinguish the quality of the circuit board from its appearance

Generally speaking, the appearance of FPC circuit boards can be analyzed and judged from three aspects;

1. Standard regulations for size and thickness.

The thickness of the circuit board is different from the size of the standard circuit board, and customers can measure and inspect it according to their own product thickness and specifications.

2. Light and color.

The external circuit board is coated with ink, which can serve as insulation. If the color of the circuit board is not bright and there is less ink, the insulation board itself is not good.

3. Appearance of welds.

Due to the large number of components on the circuit board, if the soldering is not done properly, the parts are prone to fall off from the circuit board, seriously affecting the soldering quality of the circuit board. Good appearance, careful identification, and interfaces are important, and they are used for FPC circuit boards for good and bad.

Secondly, high-quality FPC circuit boards should meet the following requirements:

1. After component installation, the phone should be easy to use, and the electrical connections should meet the requirements;

2. The line width, line thickness, and line spacing meet the requirements to avoid wire heating, open circuits, and short circuits;

3. High temperature copper is not easily detached;

4. Copper surface is not easily oxidized, which affects installation speed. After oxidation, it will quickly rupture.

5. No additional electromagnetic radiation;

6. The appearance does not deform, avoiding deformation of the shell and misalignment of screw holes after installation. Nowadays, it is all mechanized installation, and the holes, wires, and design deformation errors of the circuit board should be within the allowable range;

7. High temperature, high humidity, and special resistance should also be considered within the range;

8. The surface mechanical properties should meet the installation requirements;