Single panel, also known as single-layer board, is the simplest FPC soft board. It is generally composed of a substrate covering film, copper foil, and transparent adhesive. The copper foil needs to be etched and processed to obtain the required circuit, and the protective film needs to be drilled to expose the corresponding solder pads. After cleaning, the two are pressed together by pressing. Then electroplate or tin protect the exposed part of the solder pad. So, the big board is ready. Usually, it is also stamped into small circuit boards of corresponding shapes. Without a protective film, printing a solder layer directly on the copper foil will result in lower costs, but the mechanical strength of the circuit board will deteriorate. Unless the strength requirement is not high but the price needs to be as low as possible,

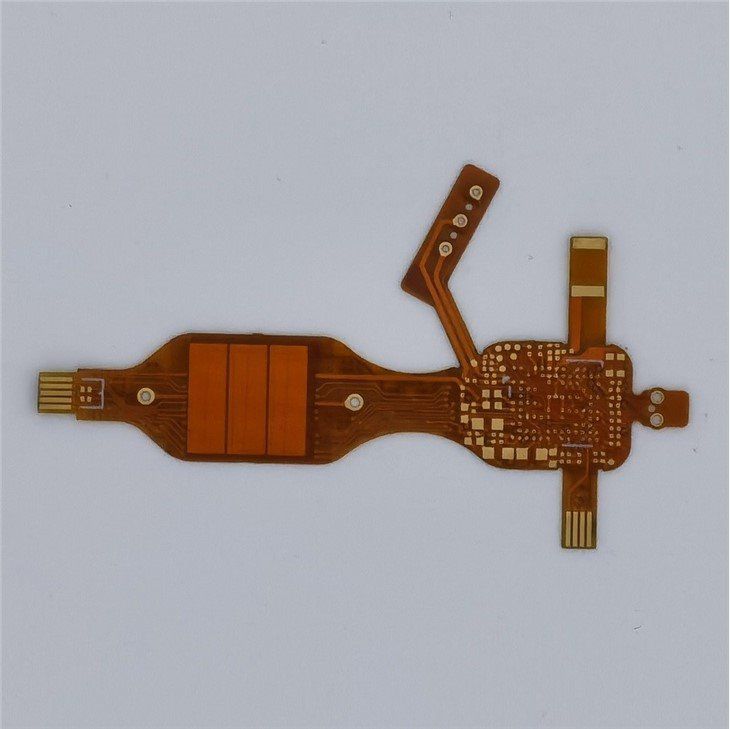

Double panel is because there are too many lines required, and it is impossible to lay all the necessary lines on one board, then lay the remaining lines on another FPC board, and then press the two boards together. We take a double-sided board, and we can see that there are wires on both sides, so this is a double-sided board.

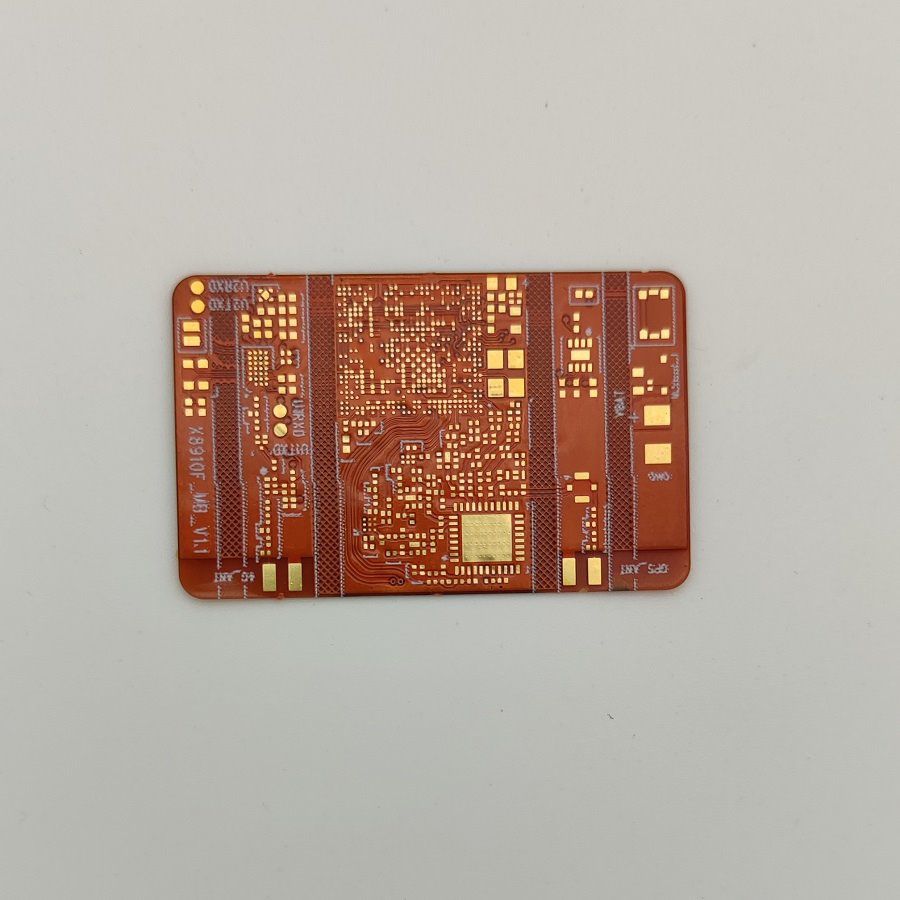

Soft hard junction board combines the flexibility of FPC and the rigidity and hardness of PCB, which is the advantage of soft hard junction board. Soft hard junction board is currently the most widely used.

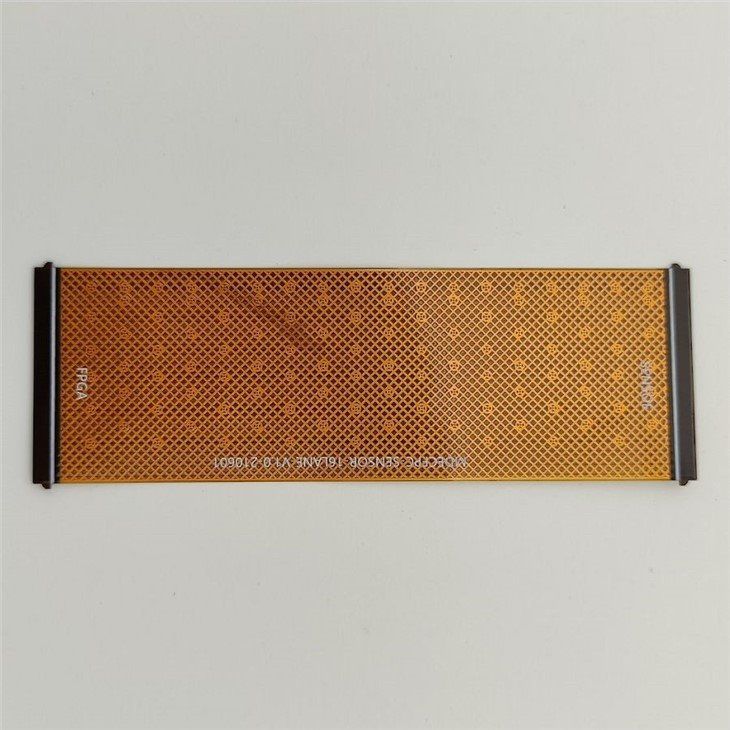

Special FPC process boards can be divided into two types: surface treatment and appearance treatment: surface treatment includes immersion gold, oxidation resistance, gold plating, tin spraying, etc. Generally, this is because special circuit boards have higher requirements than general circuit boards. In the presence of environmental factors, circuit boards that have undergone special treatment are more high-end than general circuit boards in general application industries. Shape processing is necessary because the appearance of electronic products has already been finalized, and the embedding space of circuit boards is fixed. Therefore, line type shape processing is required, and processing methods include manual shape processing, CNC machine cutting, laser cutting, etc.

According to the bonding method between the substrate and copper foil, it can be divided into adhesive rolled FPC soft board and adhesive free rolled FPC soft board. Non adhesive FPC soft board is more flexible than adhesive FPC soft board, and can have greater folding and bending strength than non adhesive FPC soft board. All parameters are better than those with adhesive, but the price is higher and the defect rate is higher. Generally applicable to high-end and precision industries.