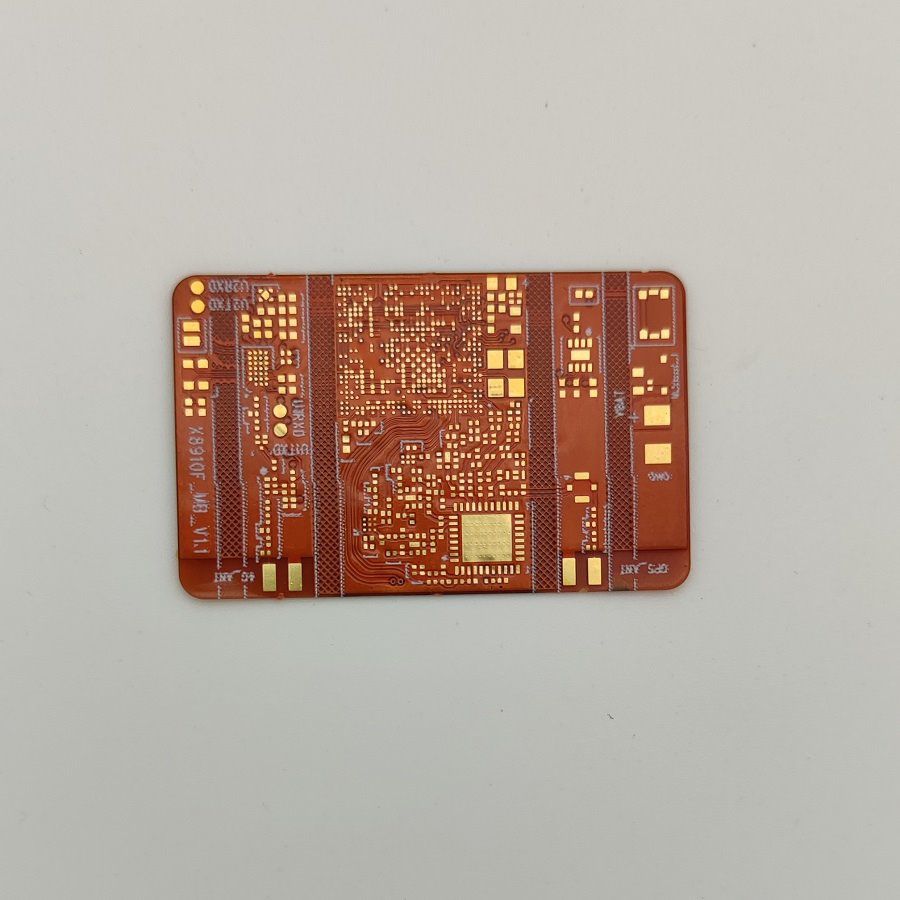

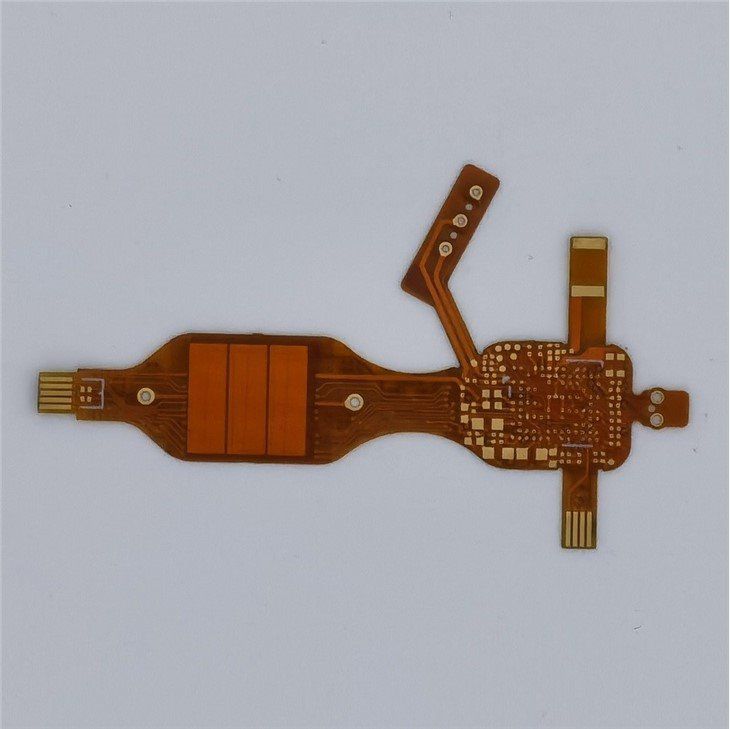

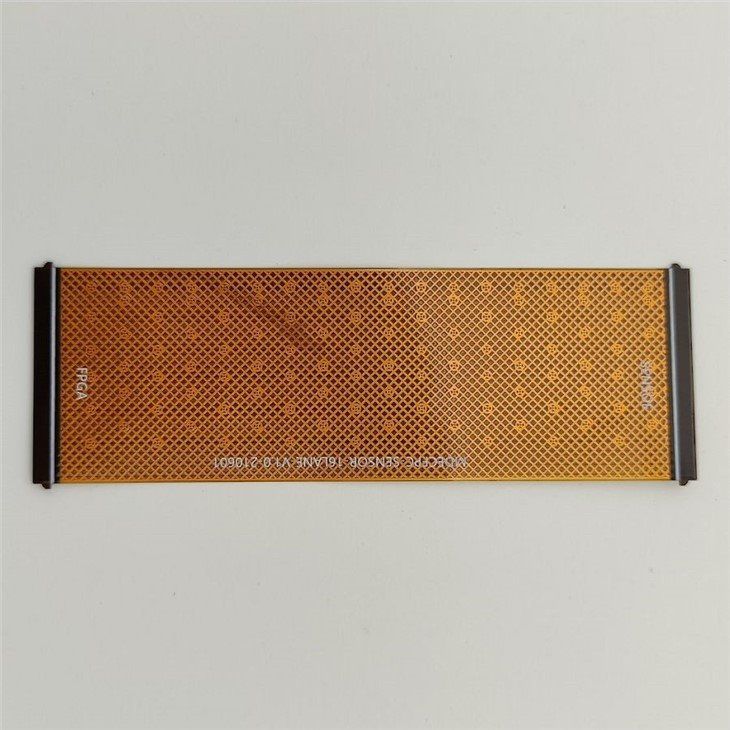

FPC flexible board refers to single-layer, double-layer, and multi-layer flexible copper foil substrates based on polyimide (PI) or polyester (PET), including adhesive and non adhesive flexible copper foil substrates. The purpose of FPC soft board testing is to establish a general rule for judging the appearance quality of FPC soft boards, which serves as a basis for the acceptance and judgment of the appearance quality of FPC soft board products. It helps to improve manufacturing processes, reduce resource waste, and unnecessary environmental pollution caused by scrap. The inspection methods mainly include visual inspection, magnifying glass, and ruler, and other applicable inspection instruments or equipment may be used if necessary.

Basic testing standards:

1. Surface appearance of the bottom film;

2. Appearance of the covering layer;

3. Deviation between the connecting plate and the covering layer;

4. Flow infiltration of adhesives and coating materials;

5. The conductor under the coating layer changes color, and after a temperature of 40 ℃, humidity of 90%, and 96 hours of humidity resistance test, it still needs to meet the requirements of voltage resistance, bending resistance, bending resistance, and welding resistance;

6. Coating omission;

7. Poor electroplating bonding.

matters needing attention:

FPC conductors must undergo surface coating treatment (rust prevention), such as electroplating, gold plating OSP、 Tin plating and other materials should be stored in an environment that avoids corrosive gases. The temperature should be within the range of 20 ℃/-5 ℃, and the relative humidity should be below 70% RH.