虽然大多数 PCB 都是按照 IPC-A-600/IPC-A-610 2 级标准生产和组装的,例如消费电子、计算机外围设备、电信和无线、物联网、机器人、LED 和照明、测试和测量、工业控制。但对于同一特殊领域,必须应用 IPC-A-600/IPC-A-610 3 级,例如汽车、医疗、军事、航空、生命支持系统等。军事和航空甚至需要 IPC 3/A 级,其标准高于 3 级。

我们可以提供按照IPC Class 3和IPC Class 3/A生产的PCB,以满足PCB行业的最高标准。

IPC-A-600 3 级 PCB 的主要验收标准

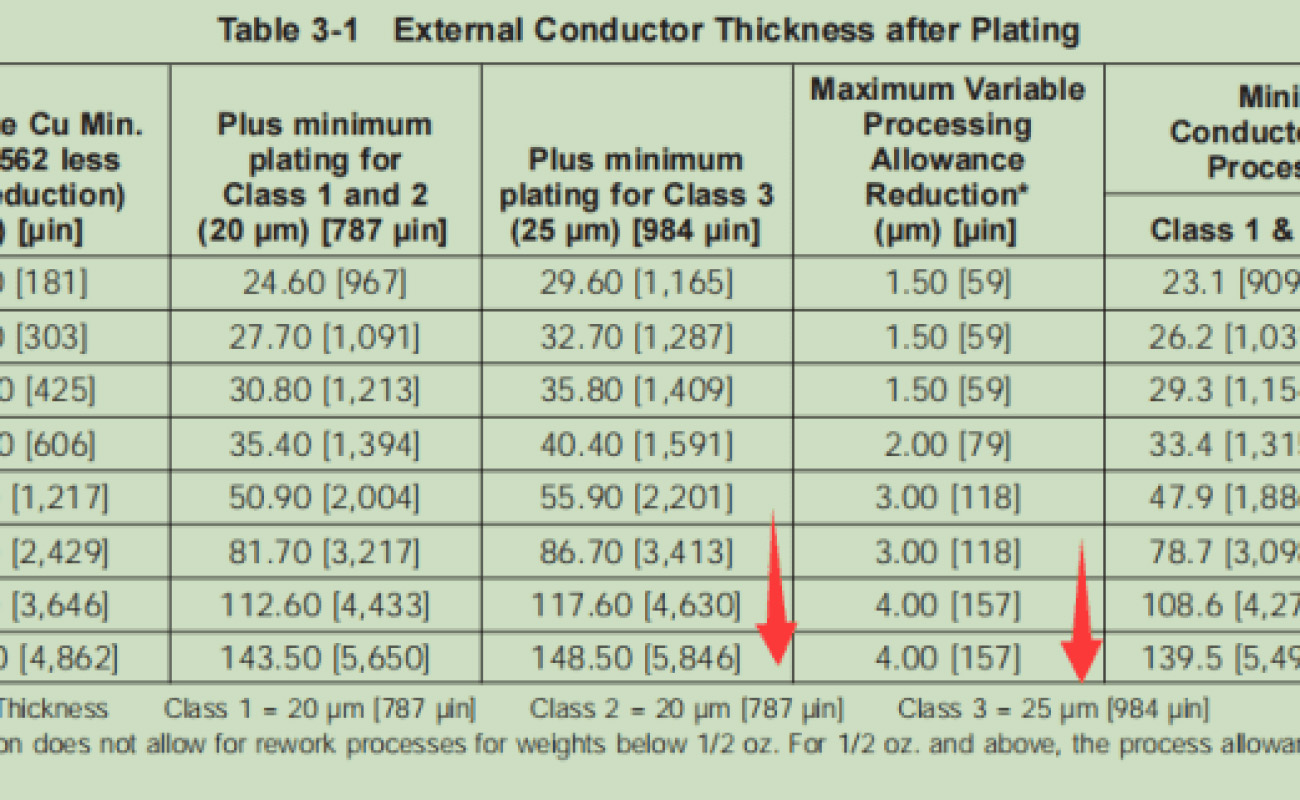

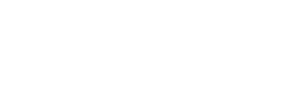

PTH孔壁的最小镀铜厚度有所不同:

IPC 2 级 PCB 验收标准: PTH壁厚>=20um。

IPC 3 级 PCB 验收标准: PTH壁厚>=25um。

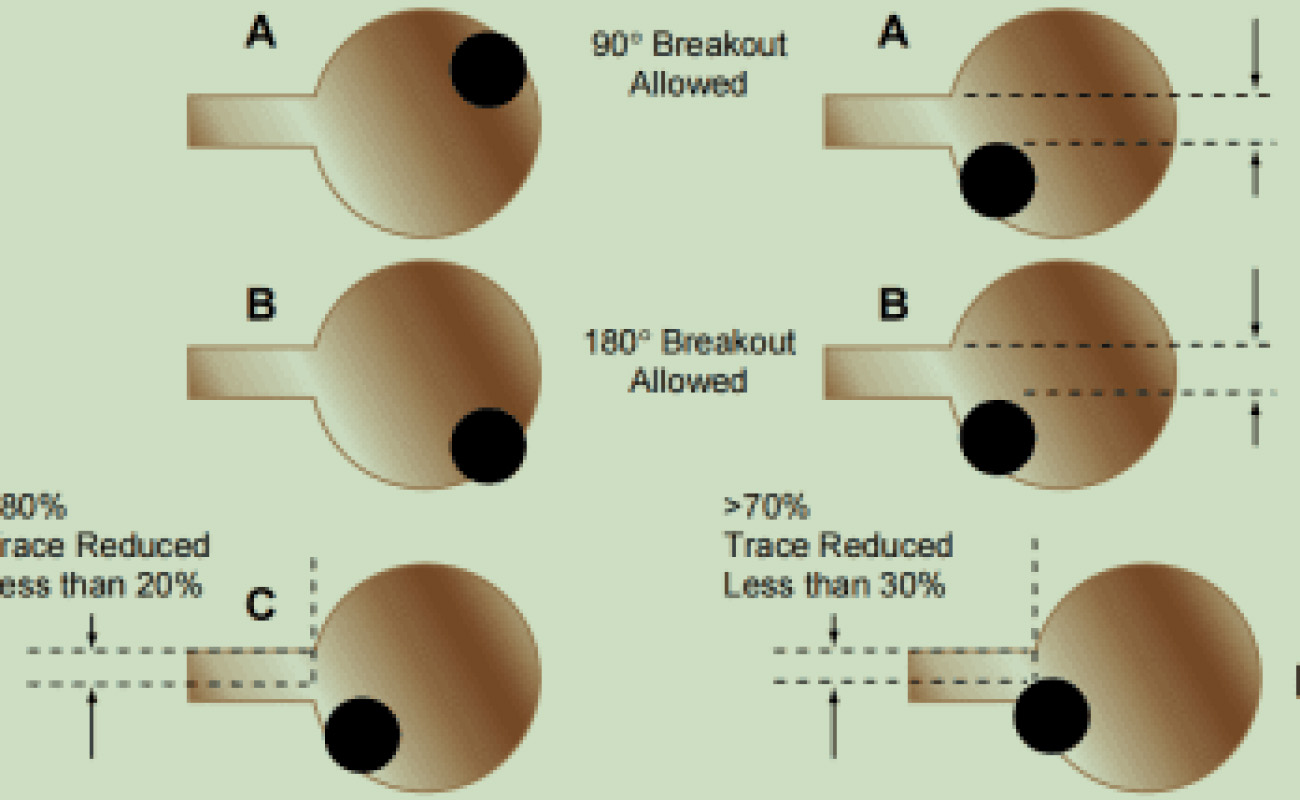

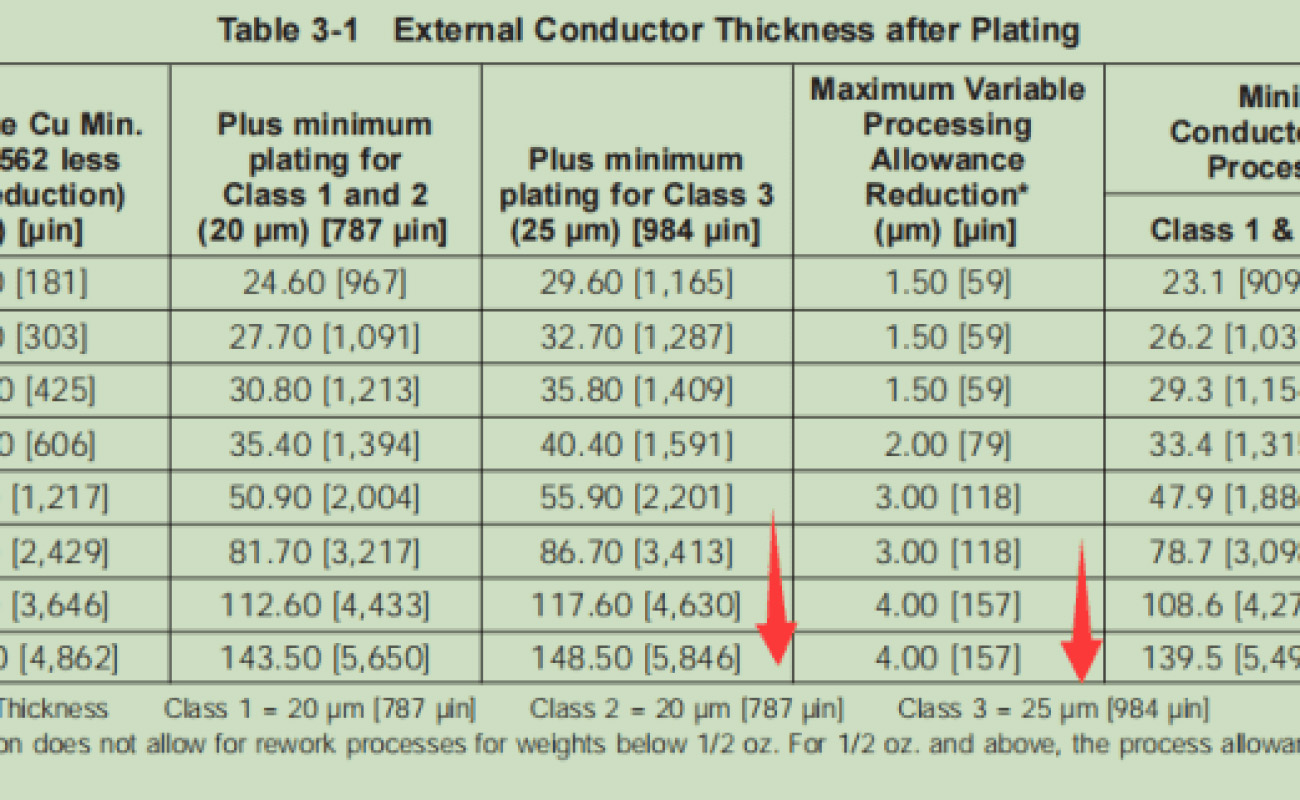

PTH最小环数:

IPC 2 级 PCB 验收标准: 90°以下时环断裂。

IPC 3 级 PCB 验收标准: 最小环尺寸:0.05mm。

铜导体宽度

IPC 2 级 PCB 验收标准: 间隙不超过最小导线间距的 30%

IPC 3 级 PCB 验收标准: 间隙不超过最小导线间距的 20%

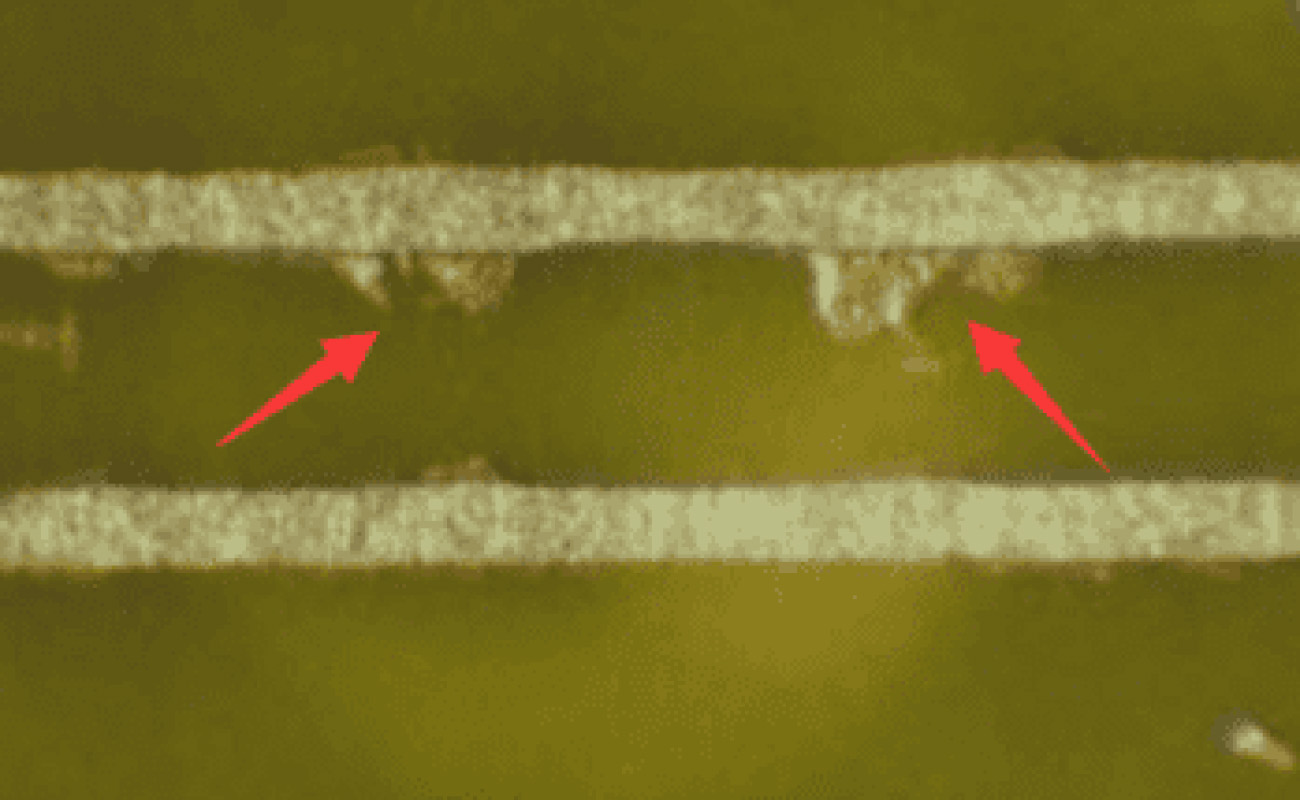

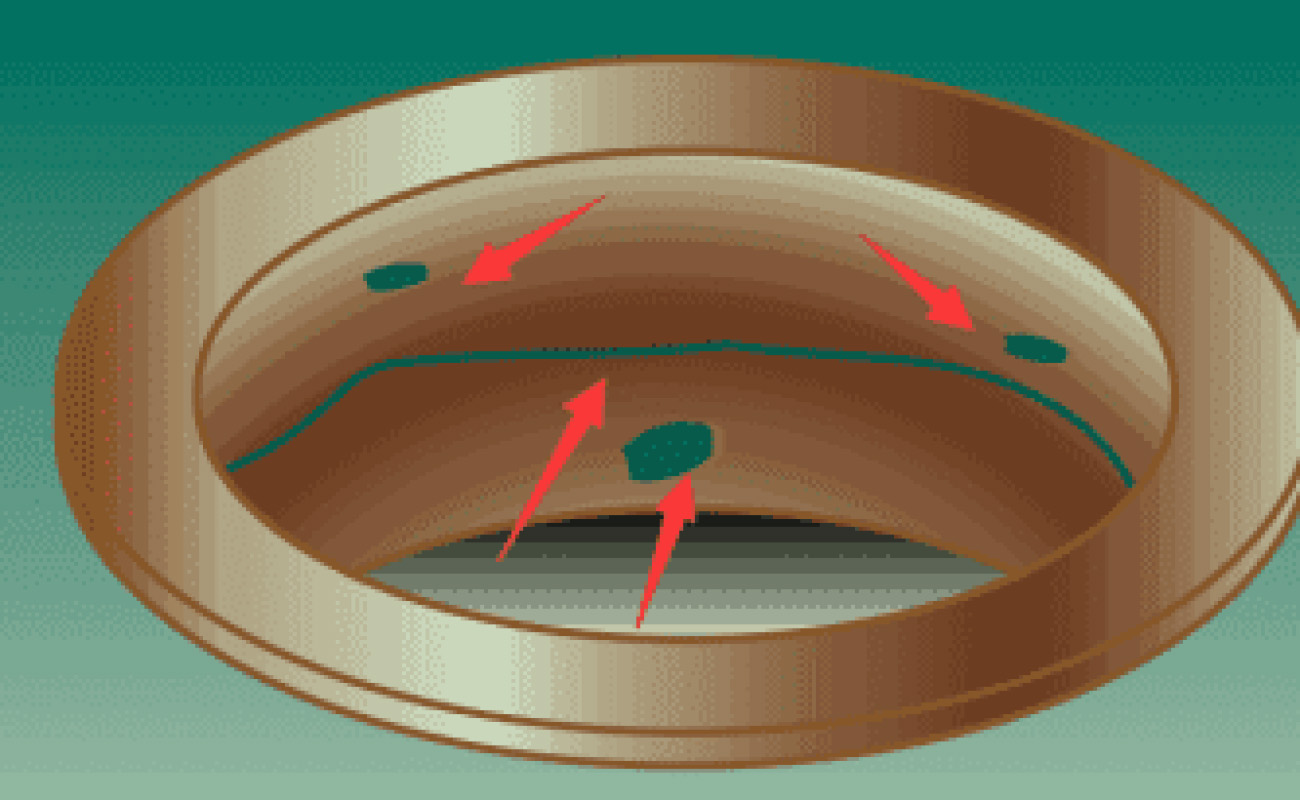

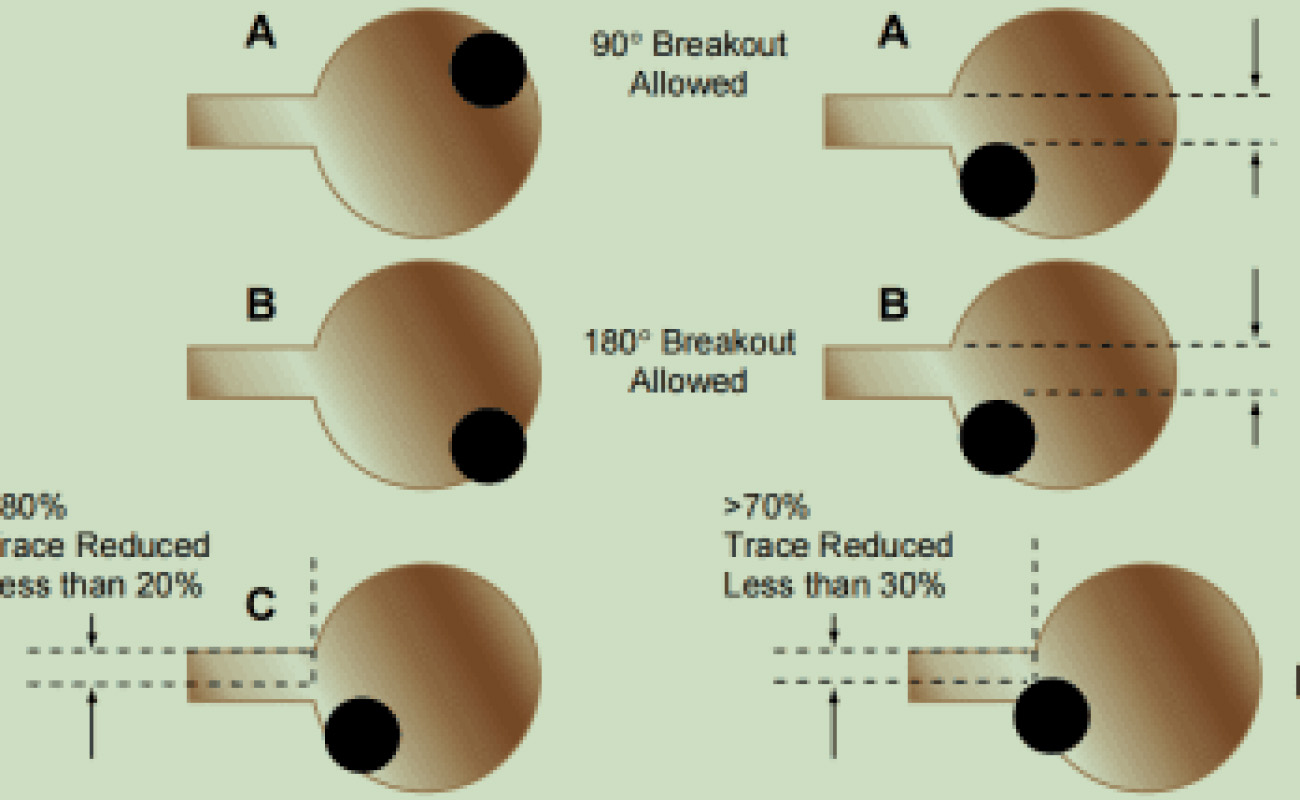

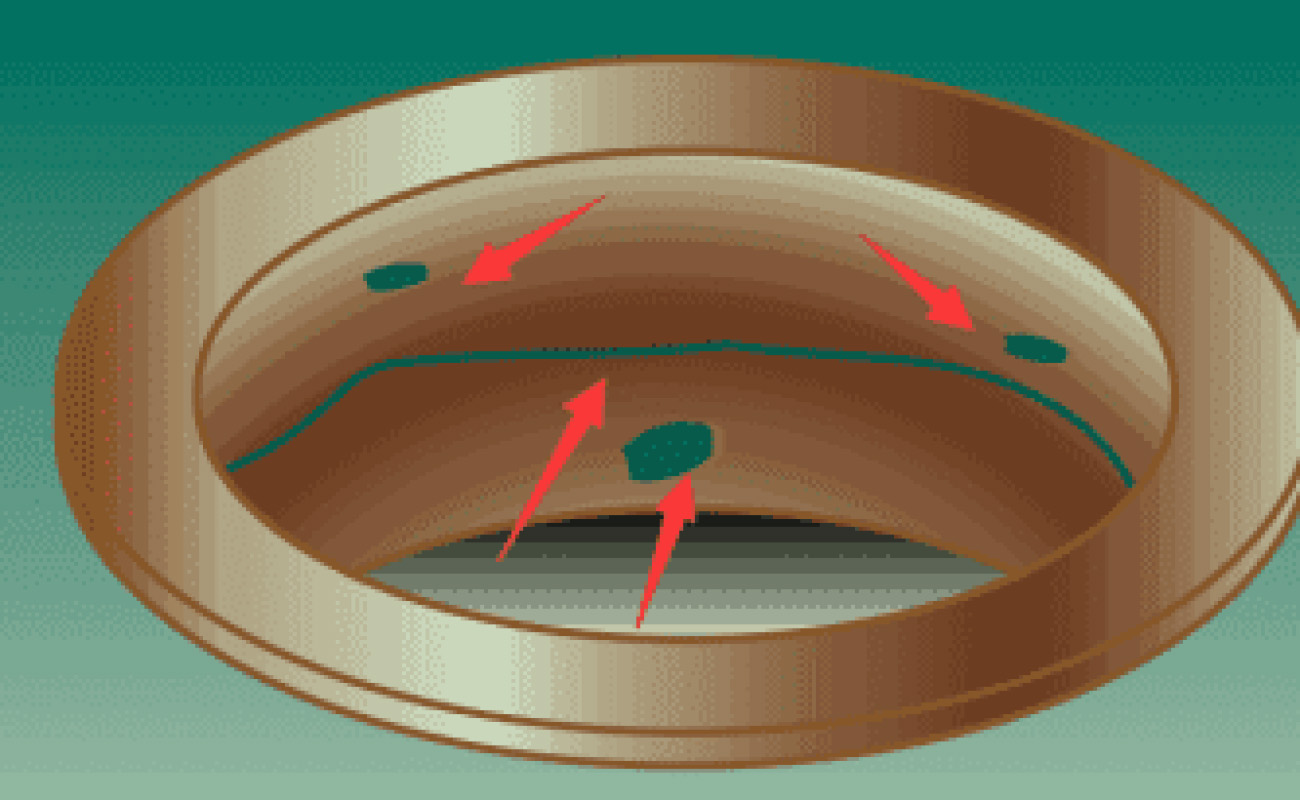

孔壁镀铜空洞:

IPC 2 级 PCB 验收标准: 孔壁内部出现空洞在一定条件下是可以接受的。

IPC 3 级 PCB 验收标准: 孔壁内部不接受任何空洞。

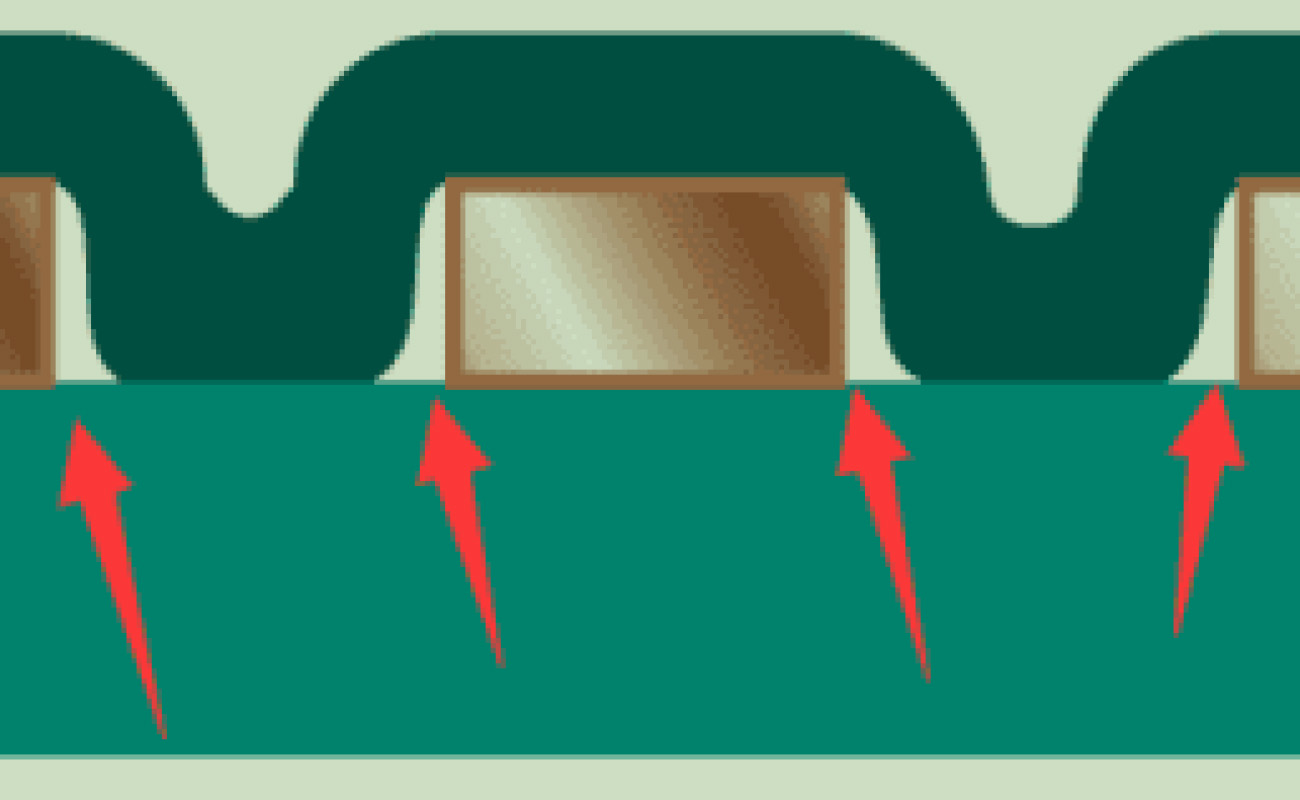

阻焊层中的苏打吸管:

IPC 2 级 PCB 验收标准: 在某些条件下,吸管间隙是可以接受的。

IPC 3 级 PCB 验收标准: 不允许有吸管间隙。

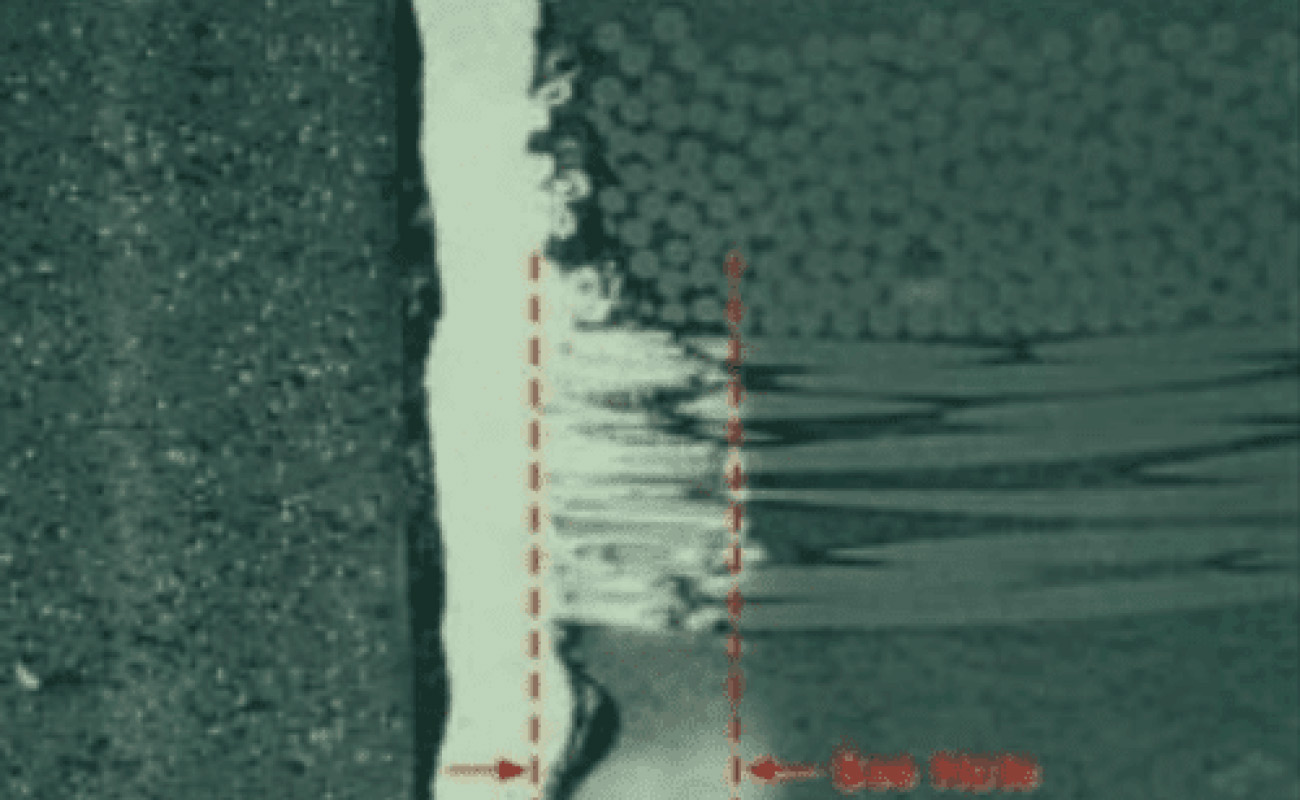

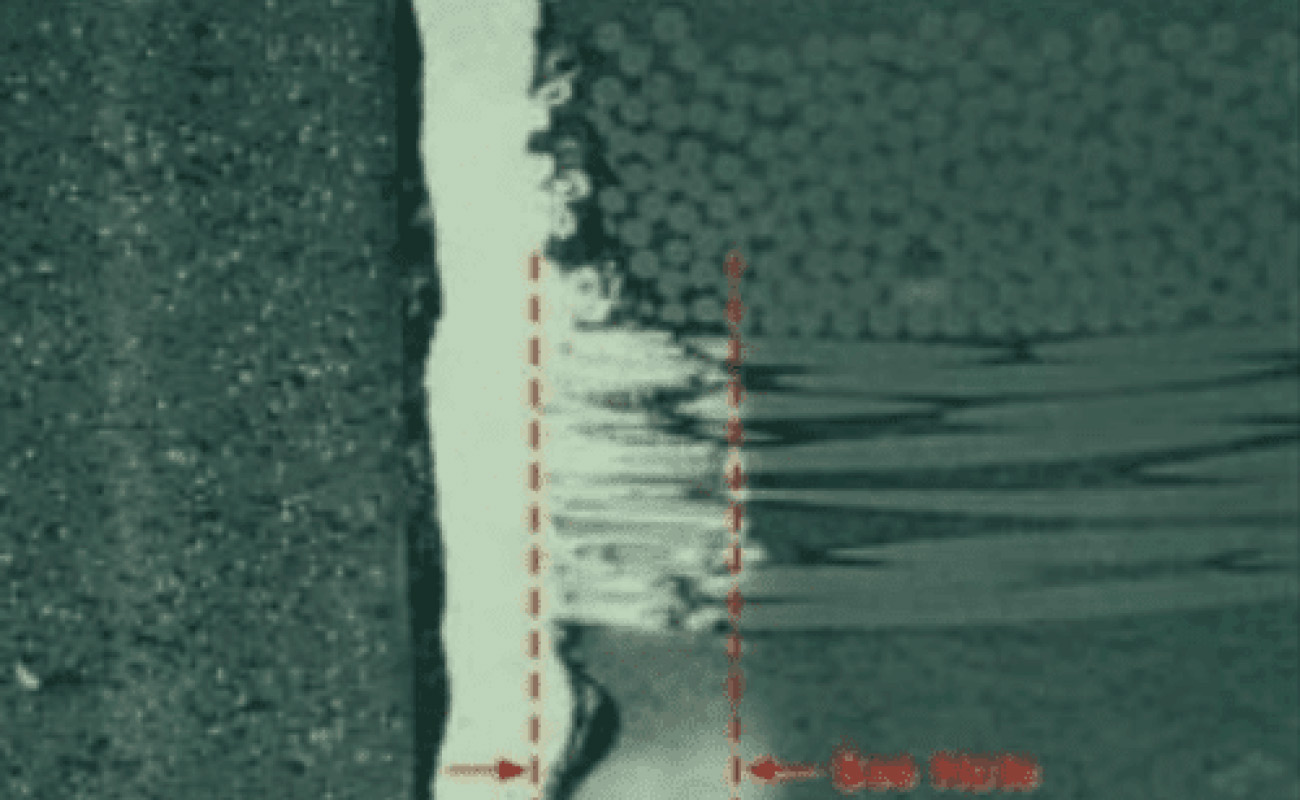

镀铜时允许的最大芯吸量。

IPC 2 级 PCB 验收标准: 吸湿排汗不超过 100 微米。

IPC 3 级 PCB 验收标准: 吸湿排汗不超过 80 微米。

IPC-A-610 3 级 PCB 组装的主要验收标准

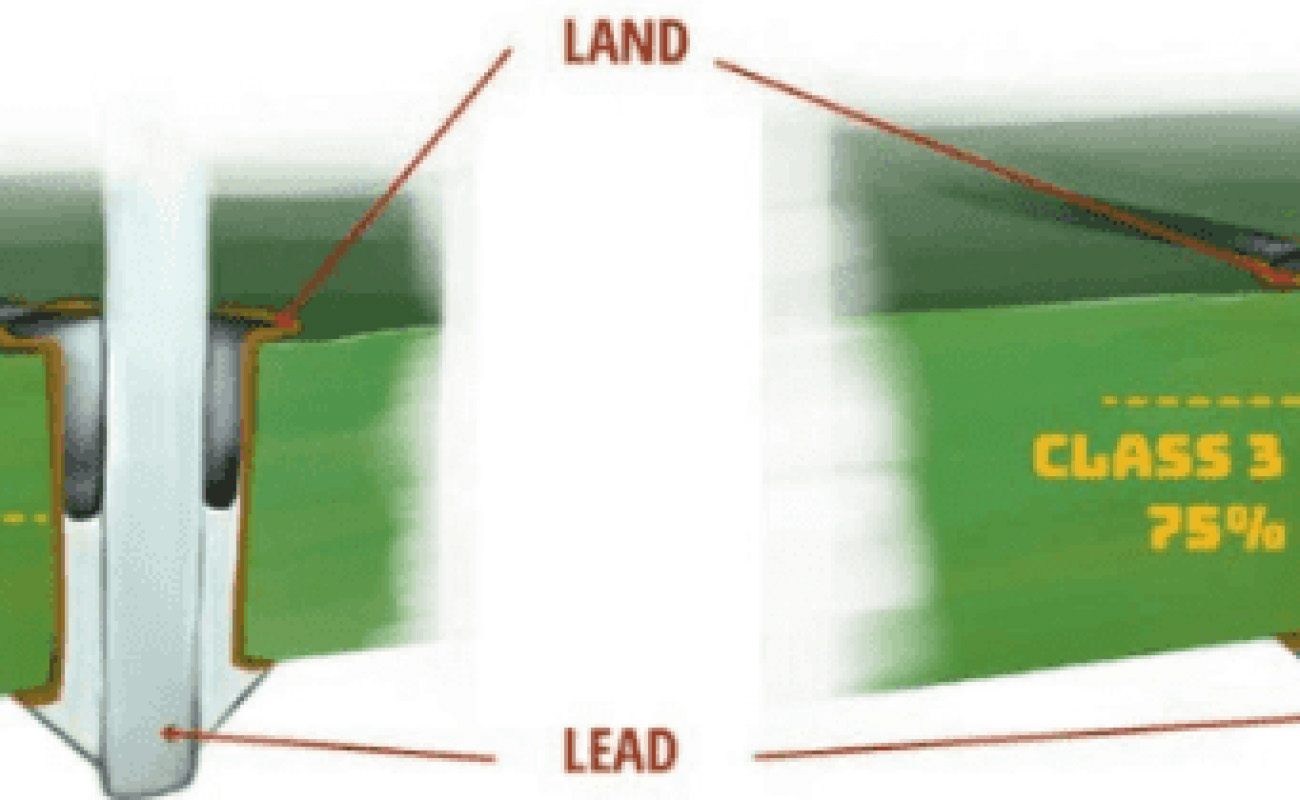

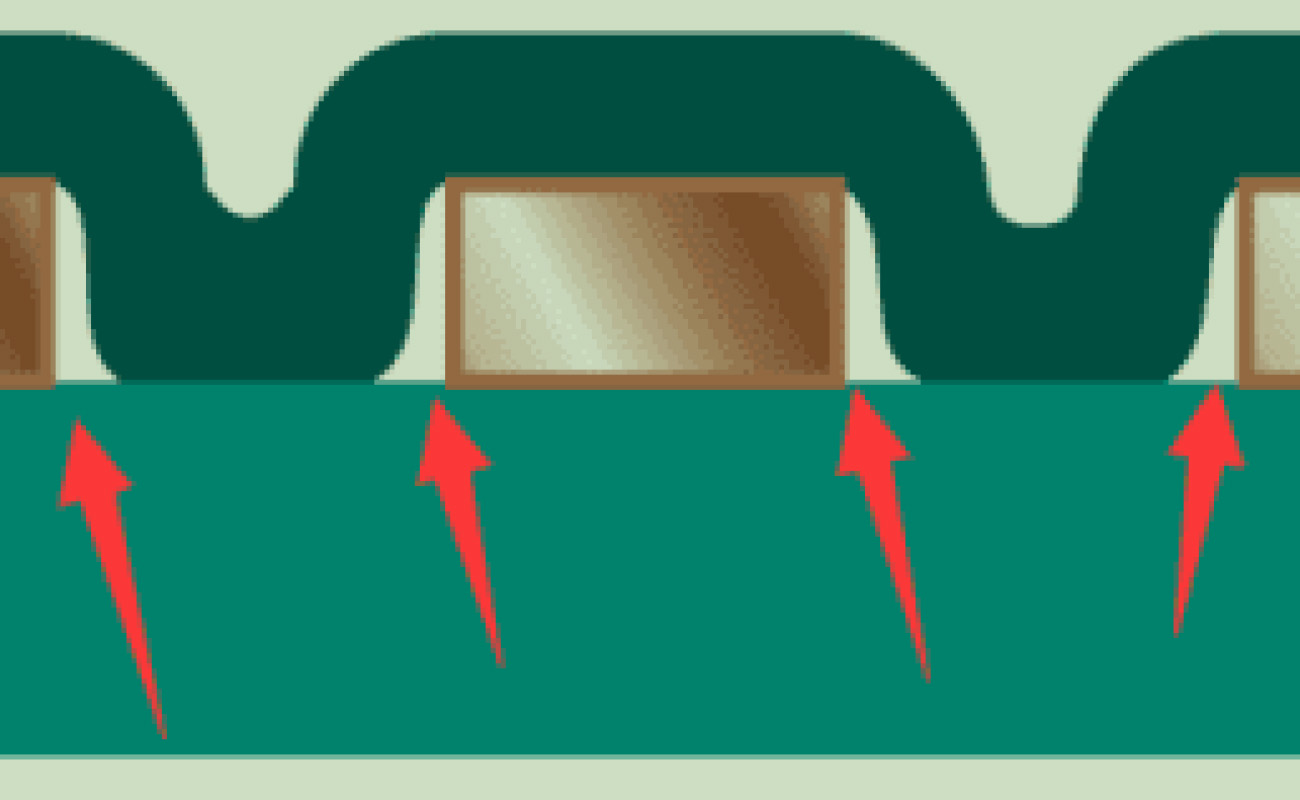

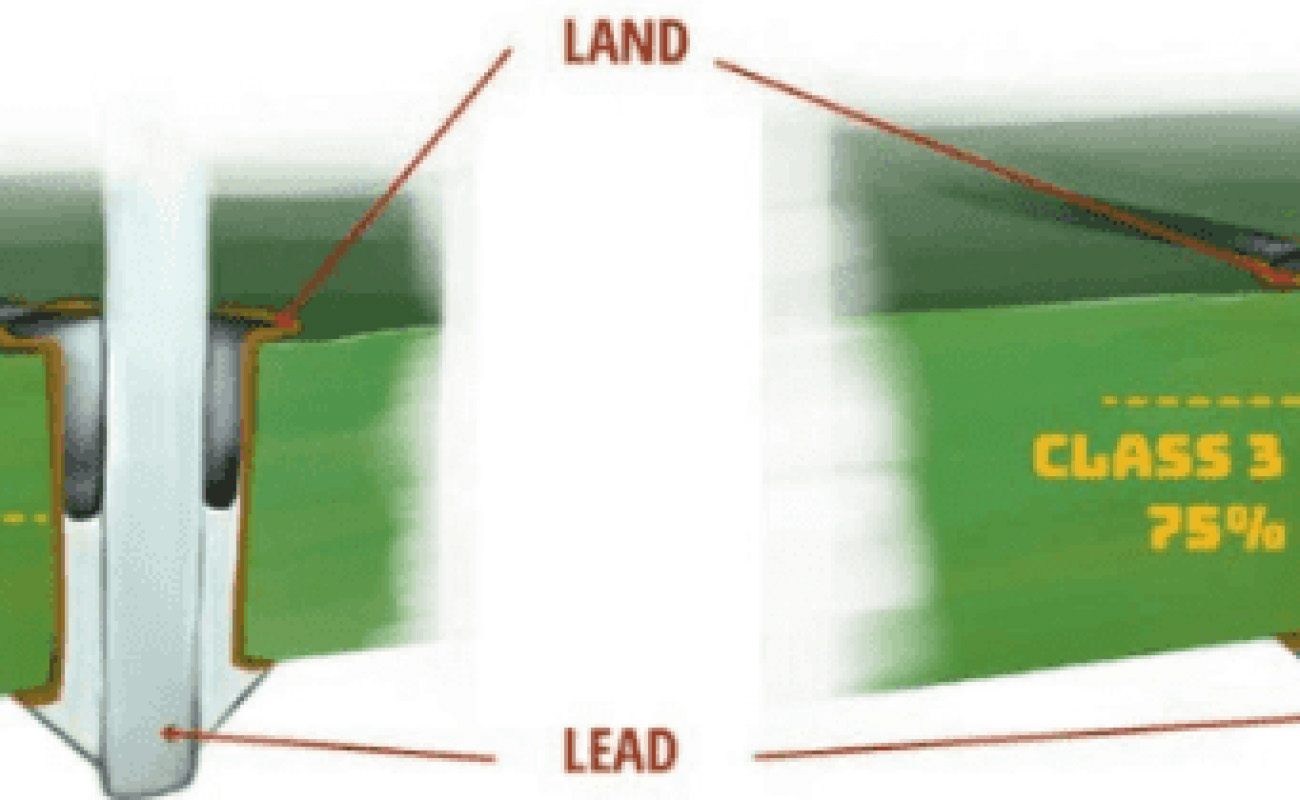

PTH 孔内填锡

至于PTH孔,重点是孔壁锡填充量。通孔引脚所需的孔壁填充量,IPC 2级为50%,但IPC 3级则需要75%。由于锡膏在小的镀铜孔(PTH)中放置时可能易碎,因此我们建议在设计时使用15 mil以上的元件引脚PTH尺寸。这样,每边将有7.5 mil的空间,使锡膏更容易填充孔壁。无论如何,PTH引线应该始终被完美焊接,并且始终需要遵循客户的标准和要求。

IPC 2 级 PCB 组装验收标准: 孔壁填充量50%以上。

IPC 3 级 PCB 组装验收标准: 孔壁填充量75%以上。

SMT 元件润湿

IPC 2 级 PCB 组装验收标准: SMD 元件垂直表面上明显有锡

IPC 3 级 PCB 组装验收标准: 最小焊点高度为 0.5 毫米,或 25% 焊料 + SMD 元件高度

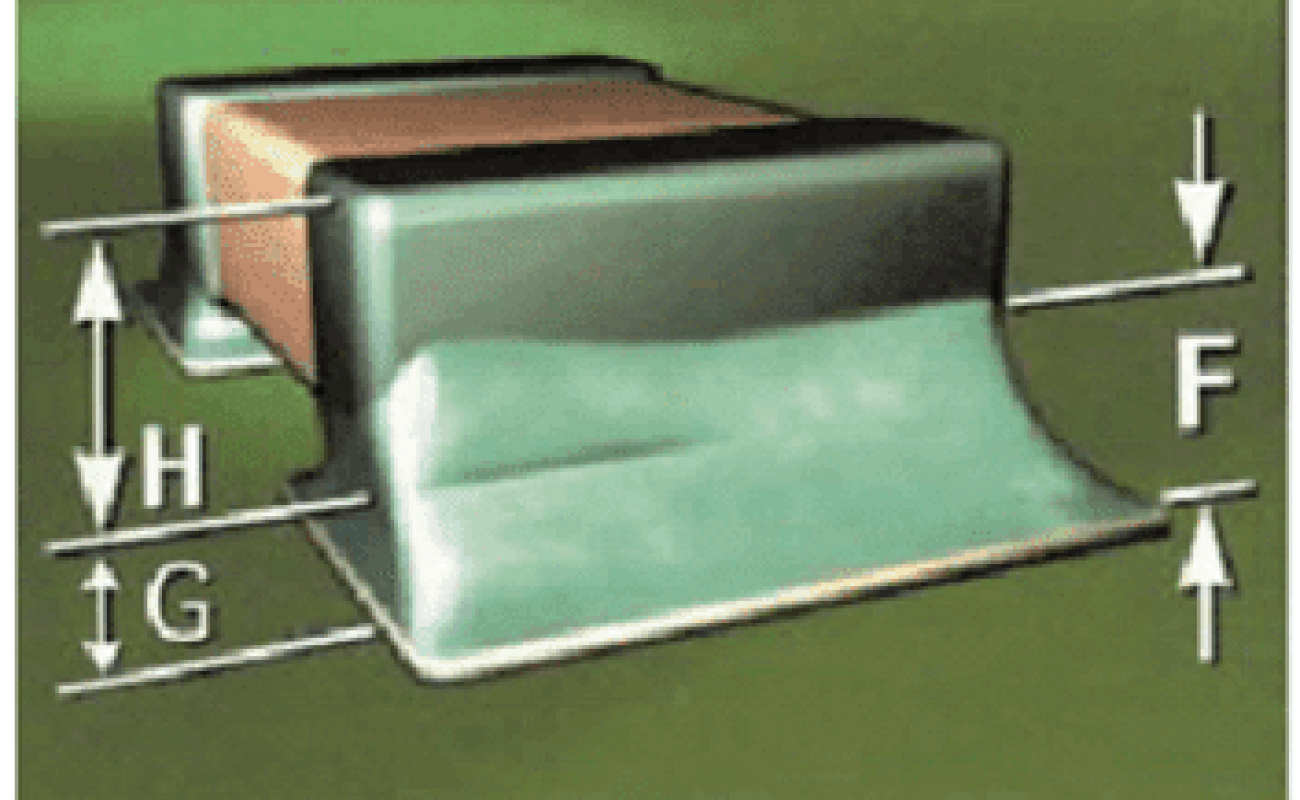

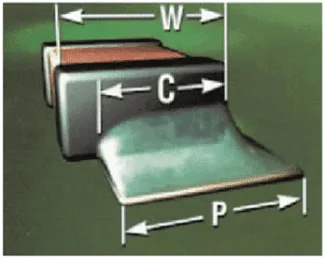

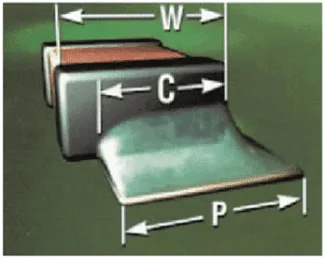

SMD 元件的侧悬垂部分

IPC 2 级 PCB 组装验收标准: 侧面突出部分小于元件/焊盘面积的 50%

IPC 3 级 PCB 组装验收标准: 侧面突出部分小于元件/焊盘面积的 25%

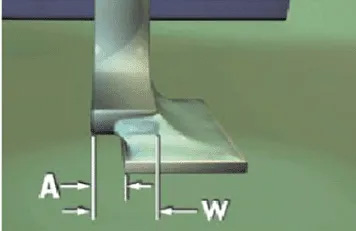

SMD 焊盘末端焊点宽度

IPC 2级标准: 端接焊点宽度至少为 SMD 元件/PAD 的 50%

IPC 3级标准: 端接焊点宽度至少为 SMD 元件/PAD 的 75%

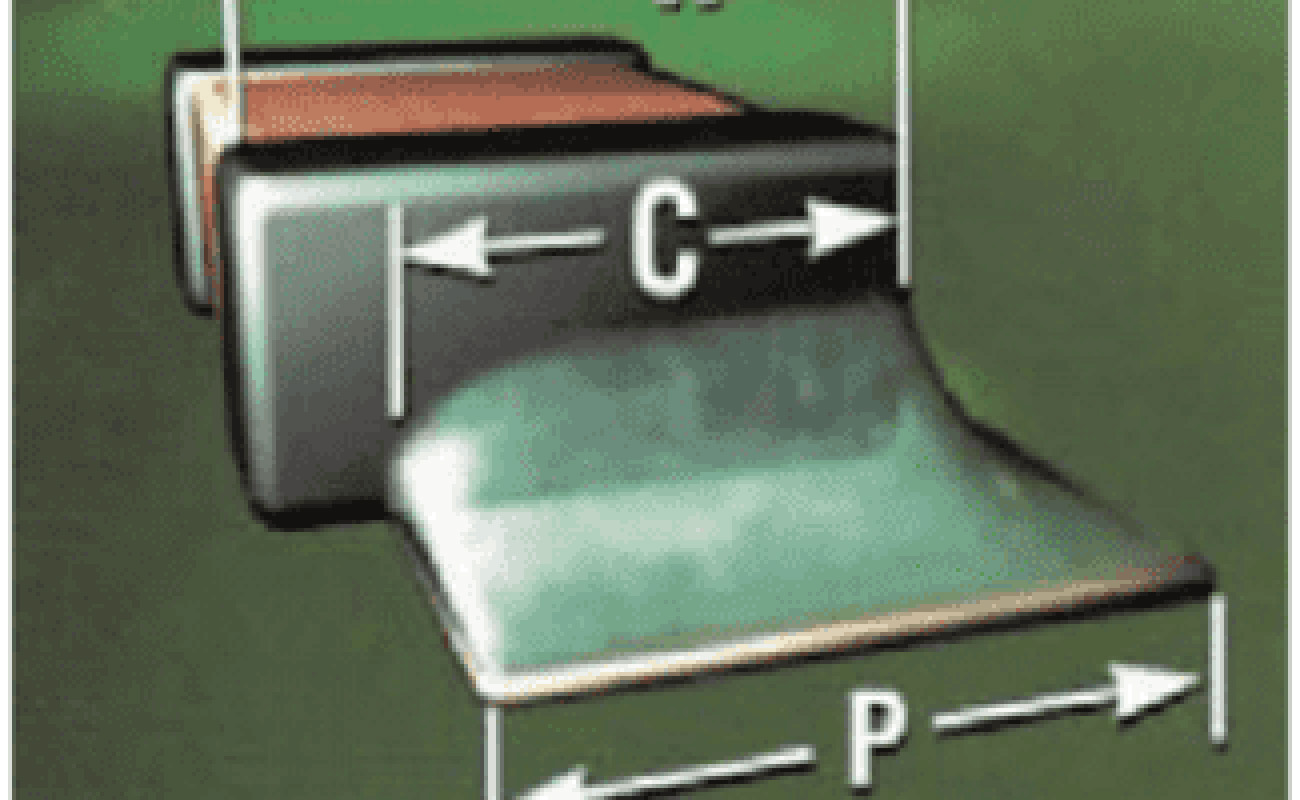

IC 引脚侧悬垂

IPC 2级标准: 侧边突出量小于引脚的50%或最小0.5mm(以较小者为准)

IPC 3级标准: 侧边突出量小于引脚的75%或最小0.5mm(以较小者为准)