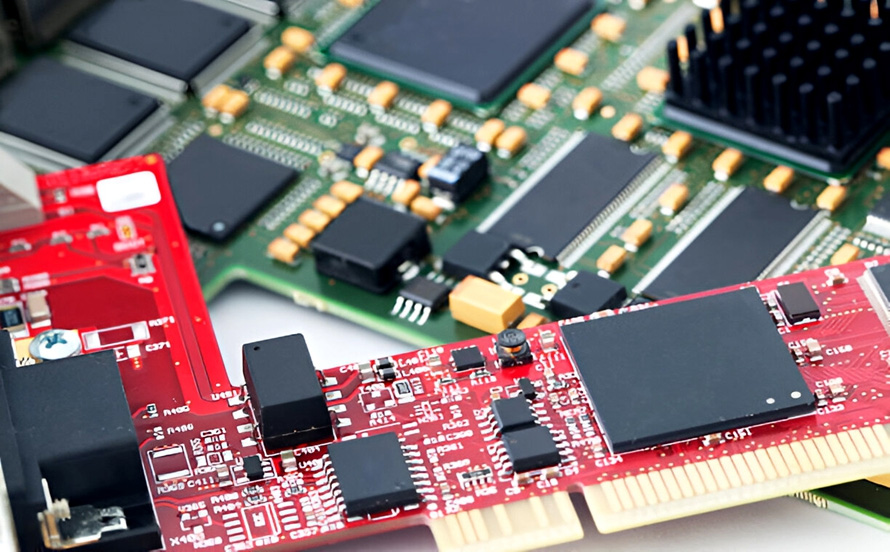

PCB components include ICs (integrated circuits), resistors, capacitors, transistors, connectors, oscillators, relays, and transformers. Below, we will further discuss some basic components and their functions:

Resistors: Resistors are classified as passive components used to resist or prevent the flow of current.

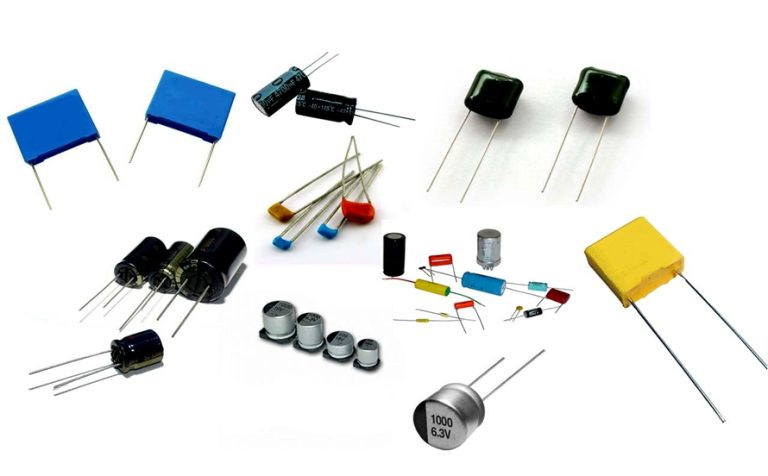

Capacitor: A capacitor is a component that can store or release energy. It stores electrical energy and prevents current from flowing when a direct current is applied.

Diode: A diode is a double ended semiconductor device that allows current to only conduct in one direction.

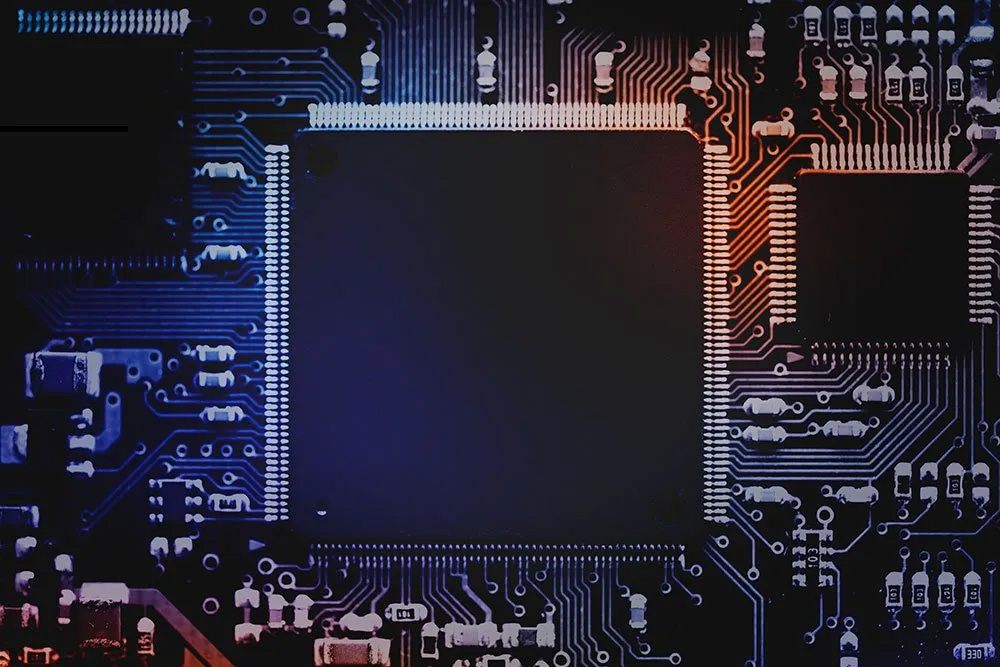

Integrated circuit: An integrated circuit is a semiconductor chip composed of miniature components such as resistors, capacitors, transistors, etc., integrated into highly functional circuits.

Transistor: A transistor is a semiconductor material that can amplify input signals.

Connector: A connector is a component that allows electrical connections between different circuits, devices, or modules.

Oscillator: An oscillator is a component that can generate clock pulses and produce precise periodic signals to synchronize and control time in electronic circuits.

Relay: A relay is an electromagnetic switch that can control high-power circuits with low-power signals, achieving electrical isolation and automation.

Transformers: Transformers are capable of transmitting electrical energy between circuits, typically by increasing or decreasing voltage while providing isolation.