compatibility problem

Therefore, it is crucial to choose the appropriate type of coating conformal material, otherwise, incompatibility between the coating and PCB components will lead to malfunctions. When selecting these materials, consideration should be given to the operating environment and chemical corrosion on the PCB surface to prevent reactions that may cause functional issues.

Potential issues with the application

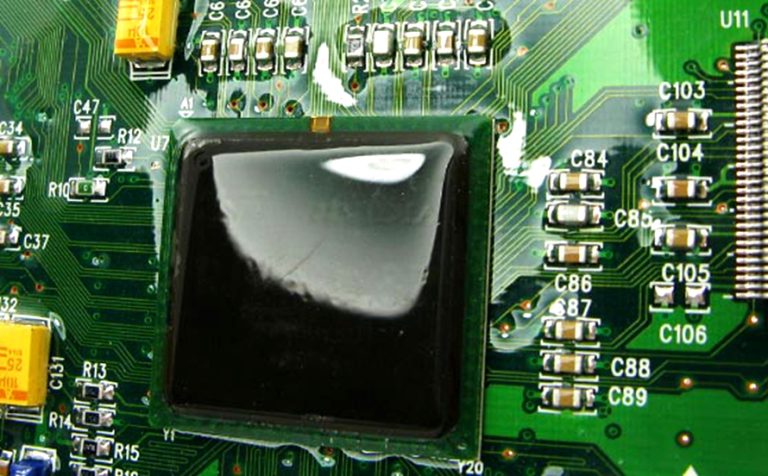

Therefore, the main problems encountered when using conformal coated PCBs include dehumidification and cracking. In addition, if the coating is too thick, it may also crack, and if the curing speed is slow, the same problem may occur.

Due to dehumidification, some uneven areas of the printed circuit board may be exposed. The surface roughness of the coating, also known as the 'orange peel effect', will definitely affect the aesthetics and performance of the coating.

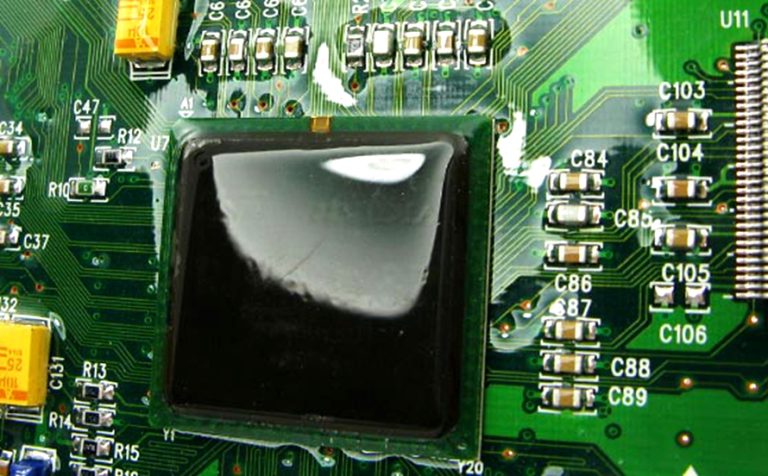

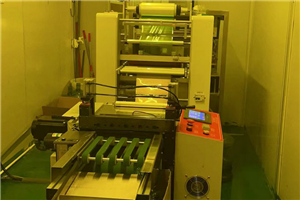

The importance of thickness and uniformity

The correct thickness and uniformity of PCB conformal coating are crucial for ensuring proper protection. Uneven coating may lead to poor areas, causing problems with insulation and moisture-proof layers. These PCB conformal coating services should be strictly controlled to achieve perfect results.

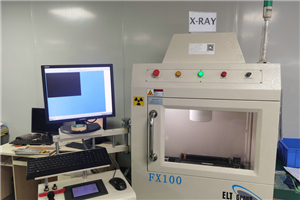

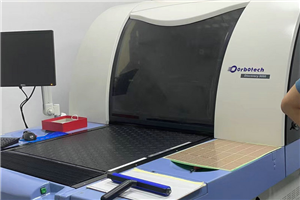

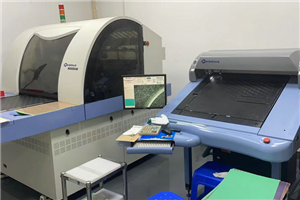

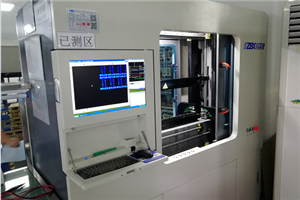

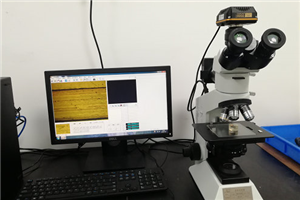

PCB qualified coating inspection

We use ultraviolet rays and microscopes to inspect the coating effect on PCBs. We use ultraviolet radiation to help determine how well the coating covers and whether there are inconsistencies or gaps.

We use microscopes to detect microscopic defects related to the proper functioning of denser components, such as bubbles or thin spots.

Considerations for lifespan and durability

The durability of conformal coated PCB components depends on their operating environment and application quality.

We will provide regular maintenance and professional repair services when necessary. The coatings and application technologies we choose are tailored to ensure that they do not withstand certain environmental pressures, thereby maintaining sustained performance and reliability.

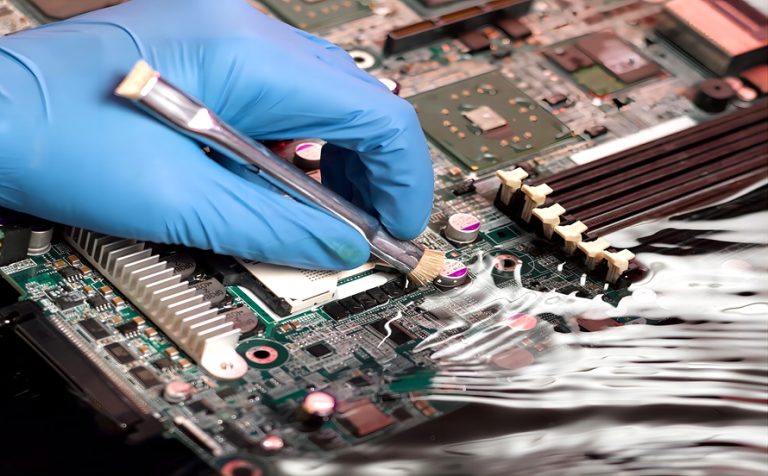

Precautions for repairing conformal coatings

Conformal coating PCB repair involves selectively removing damaged areas using solvents or mechanical methods, followed by thorough cleaning. Repainting should be accurate and not damage the protective integrity of the PCB.