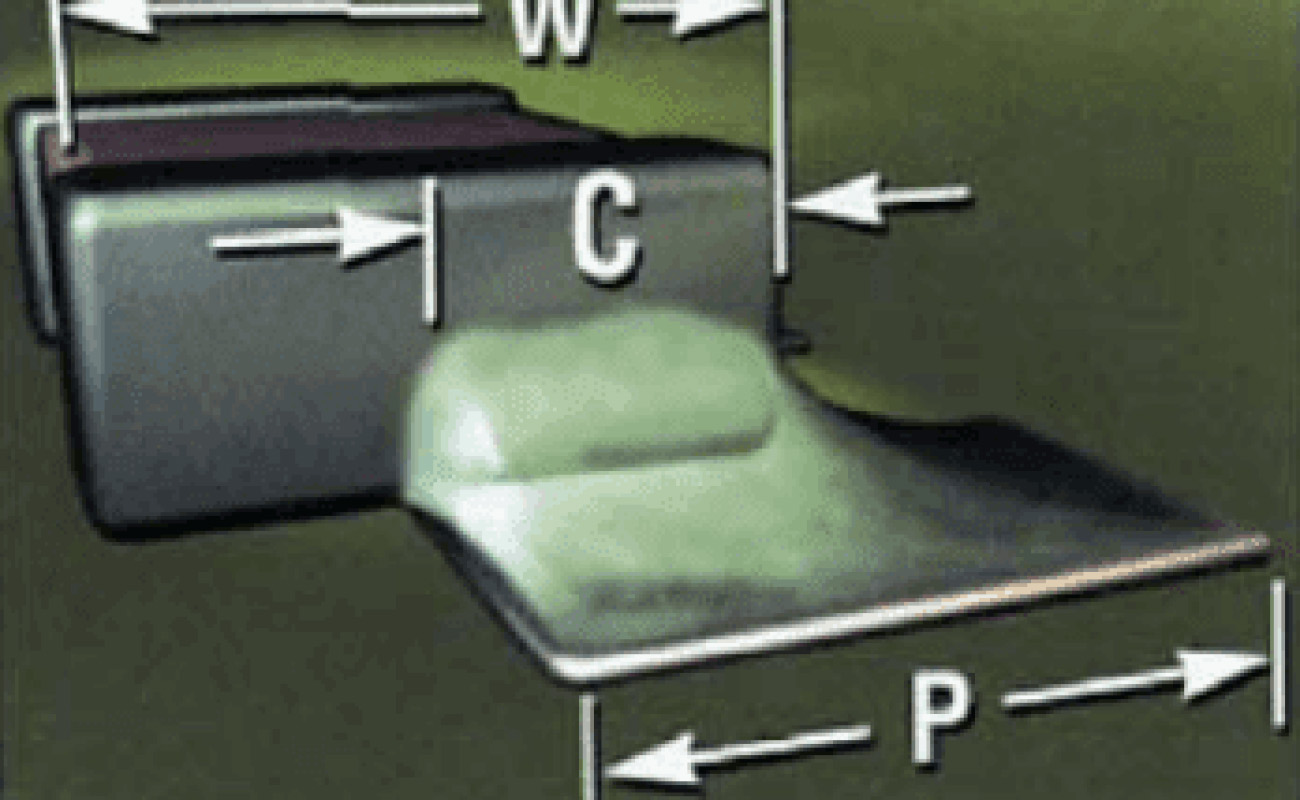

The width (C) of the end solder joint shall be at least 50% of the solderable end width (W) of the component or 50% of the pad width (P), whichever is smaller.

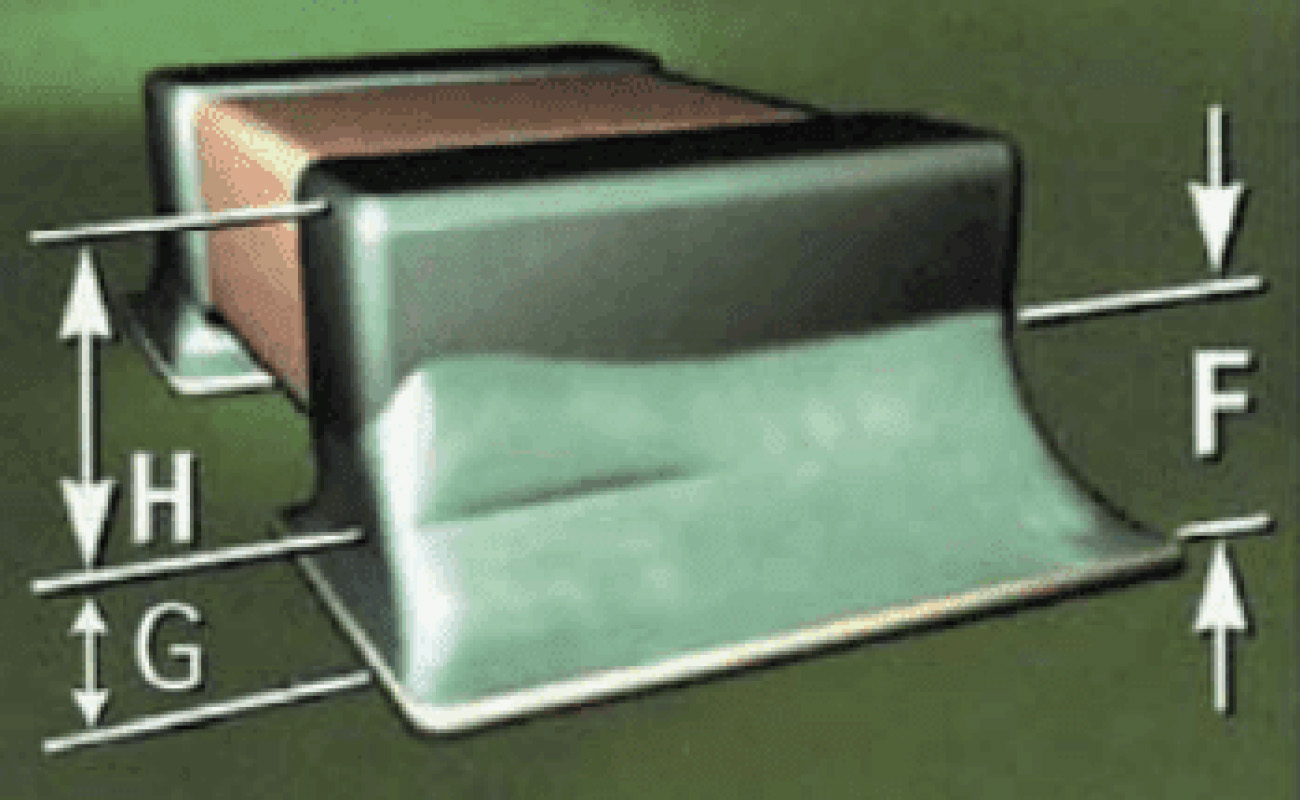

The minimum solder joint height (F) is 25% of the solder thickness (G) plus the solderable end height (H) or 0.5 millimeters, determined by the smaller of G and H.

The maximum height of a solder joint is the thickness of the solder material plus the height of the solderable end of the component.

The following figure shows the defect: the width of the solder joint is less than 50% of the width of the smaller solder joint.

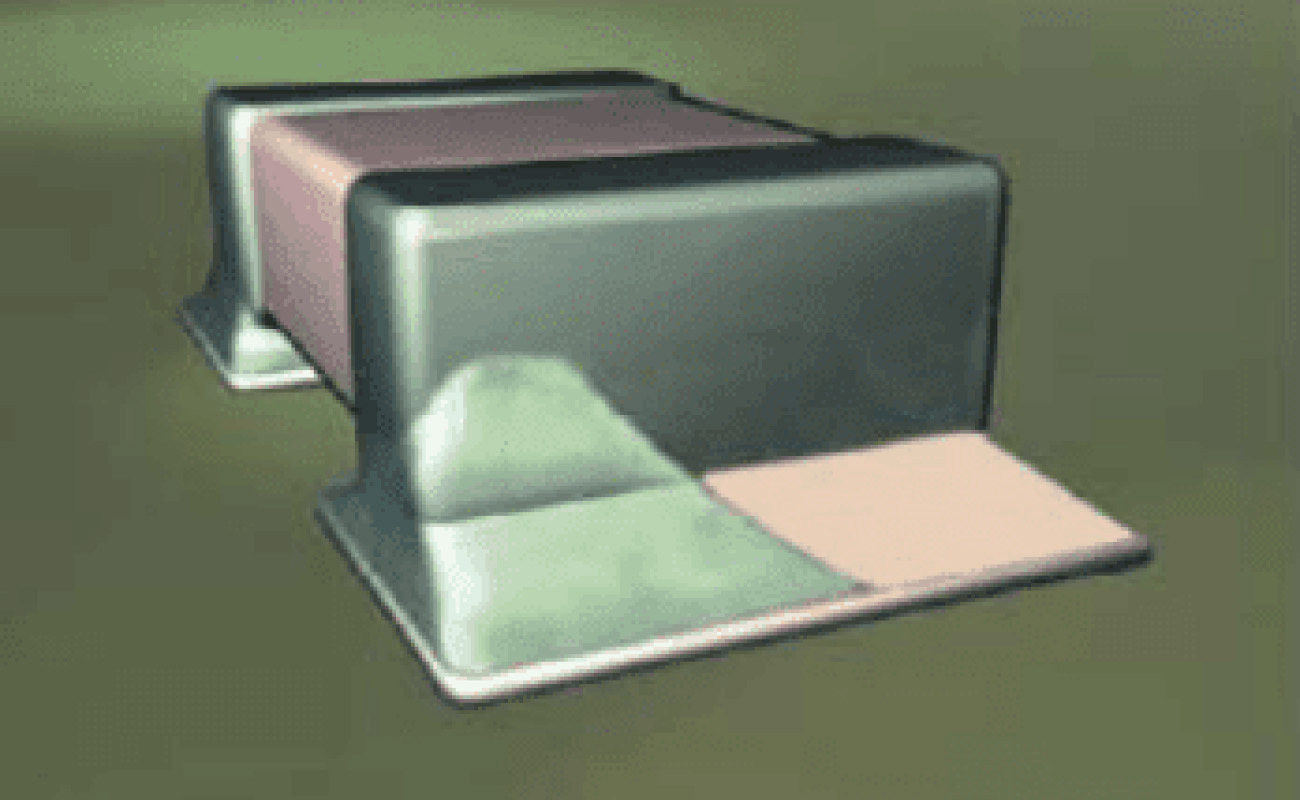

The following figure shows the defects: no solder joint crawling height, insufficient solder, and no wet solder joints on the vertical surface of the solderable end of the component.

The following figure shows the acceptable welding situation: the maximum height of solder joint (E) can exceed the solder pad or extend to the top of the metal coating of the solderable end cap, but cannot extend to the top of the component body.

Get a Quotation

Your trusted partner and one-stop supplier for FPC/PCB manufacturing, component procurement, FPC/PCB assembly, and electronic manufacturing. With over 16 years of experience, we have been providing high-quality FPC/PCB at competitive prices to over 1000 customers worldwide. Our company has passed ISO9001:2015 certification and UL certification, and all of our products have undergone 100% electronic testing and passed AOI and X-RAY inspections to meet the highest industry standards. Therefore, please obtain an immediate quote from our sales team as we will handle the remaining matters.