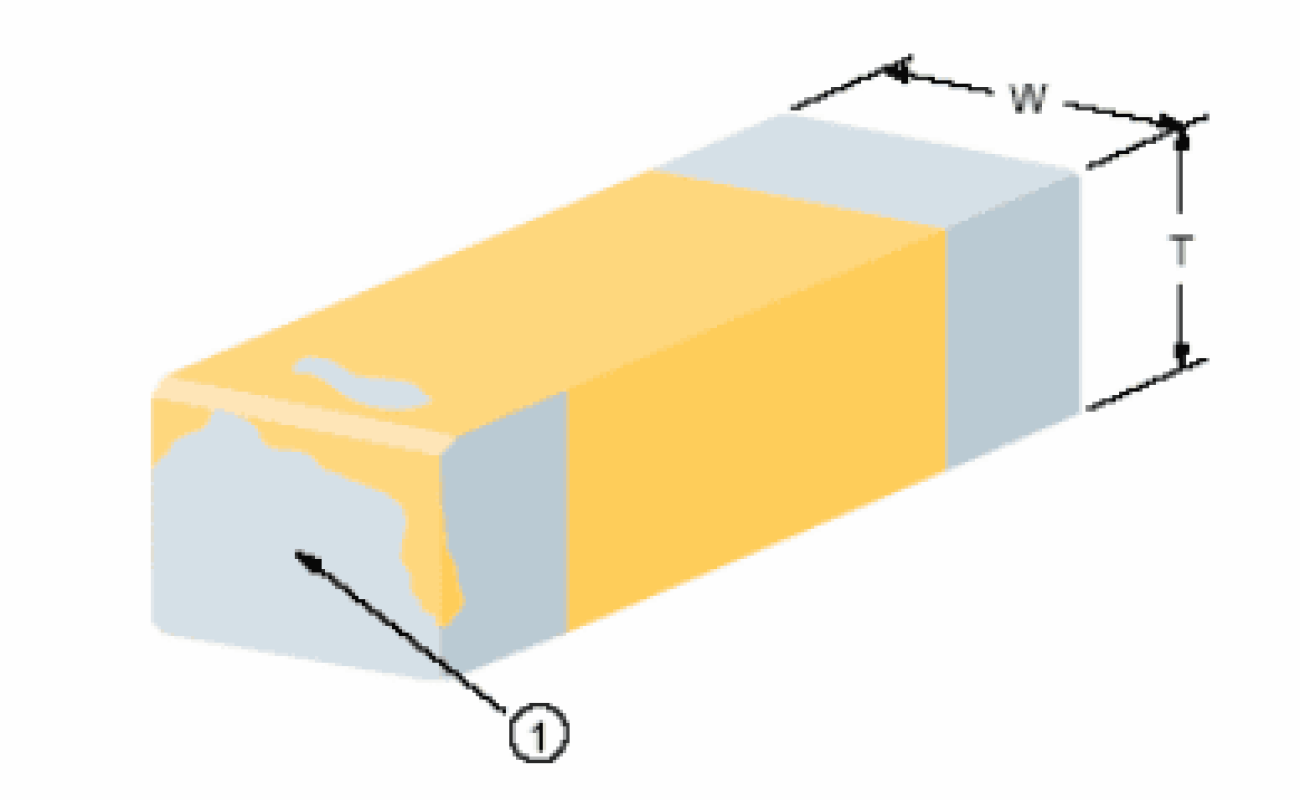

Acceptable: Any edge peeling shall be less than 25% of the component width (W) or component thickness (T).

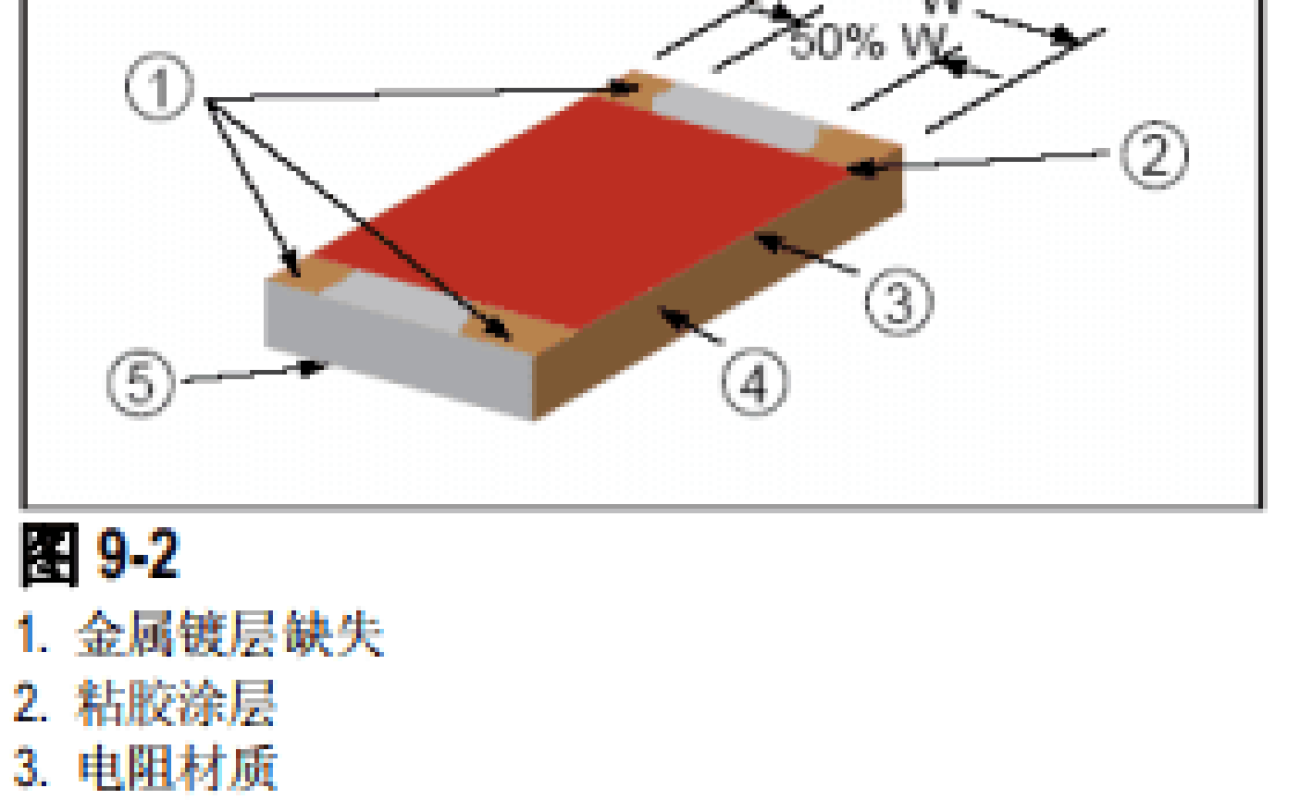

The missing metal coating at the top of the end is up to 50% (per end).

The surface is undamaged. The component body has no scratches, cracks, gaps, or broken wires. The identification marks are clear and distinguishable.

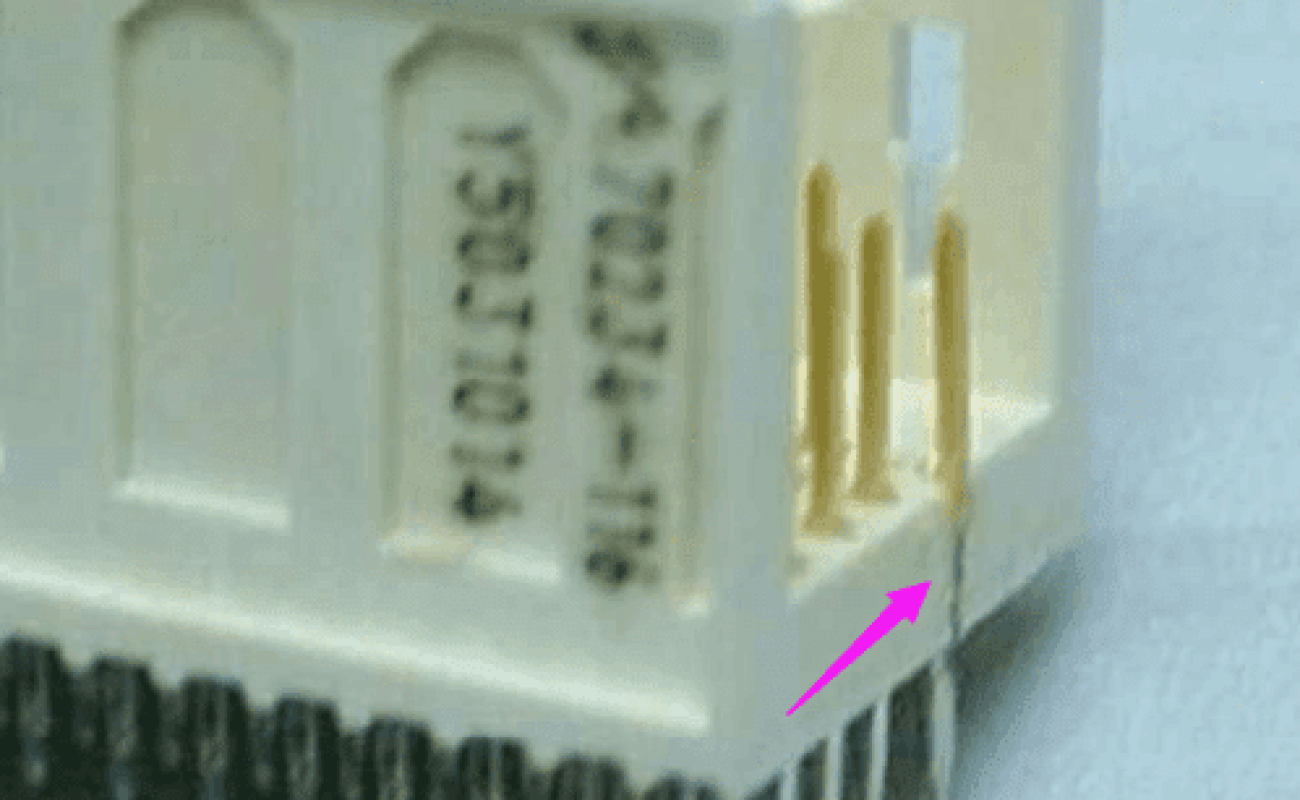

The following figure shows the defect: the metal coating at the top of the end is missing by more than 50% (per end).

The following figure shows the defect: the metal coating at the top of the end is missing more than 50%.

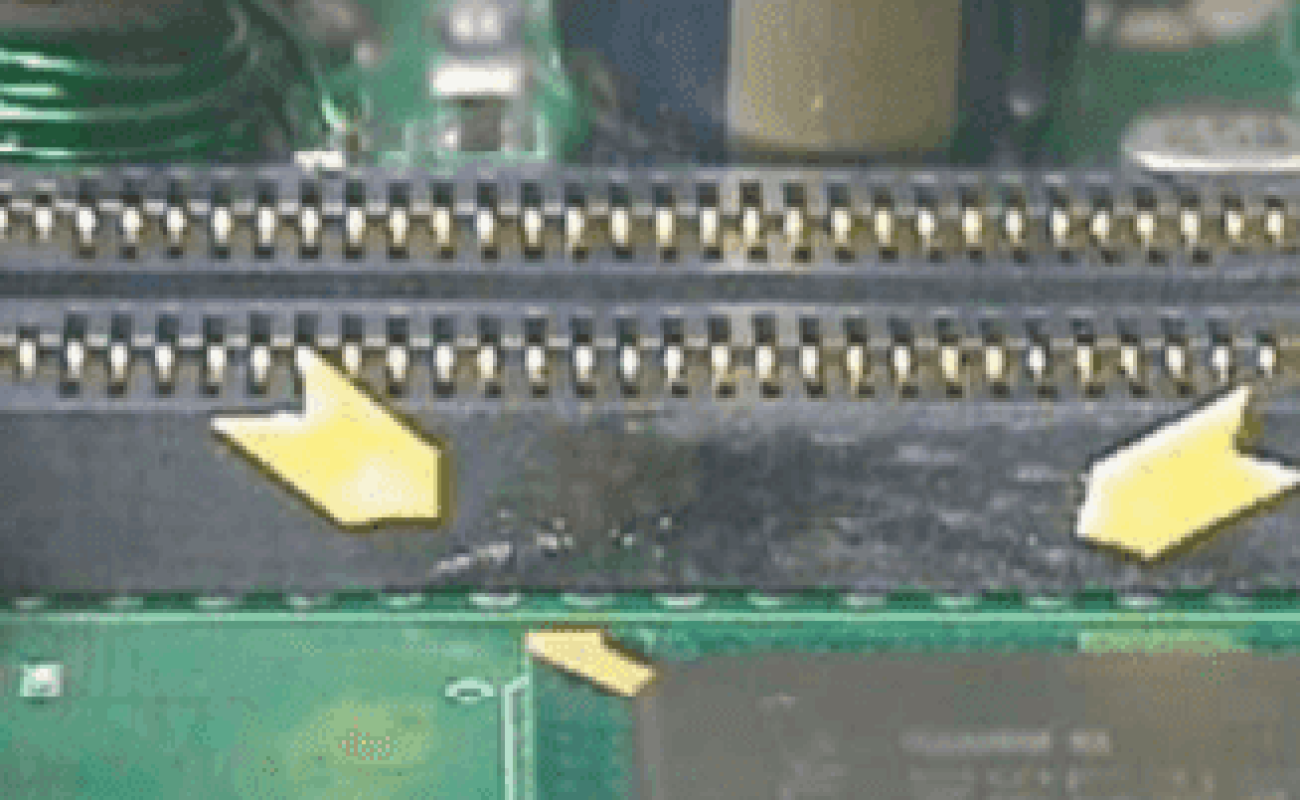

The following figure shows a process warning: there are dents or indentations on the plastic component body that do not extend to the sealing of the pins or expose the functional essence inside.

Cracks or other deformations can affect the mechanical integrity or functionality of the casing.

The distance between the bend of the contact pin and the center is greater than 25% of the thickness/diameter of the contact pin.

Burnt or other damage affects the shape or other functionality of disk loading.

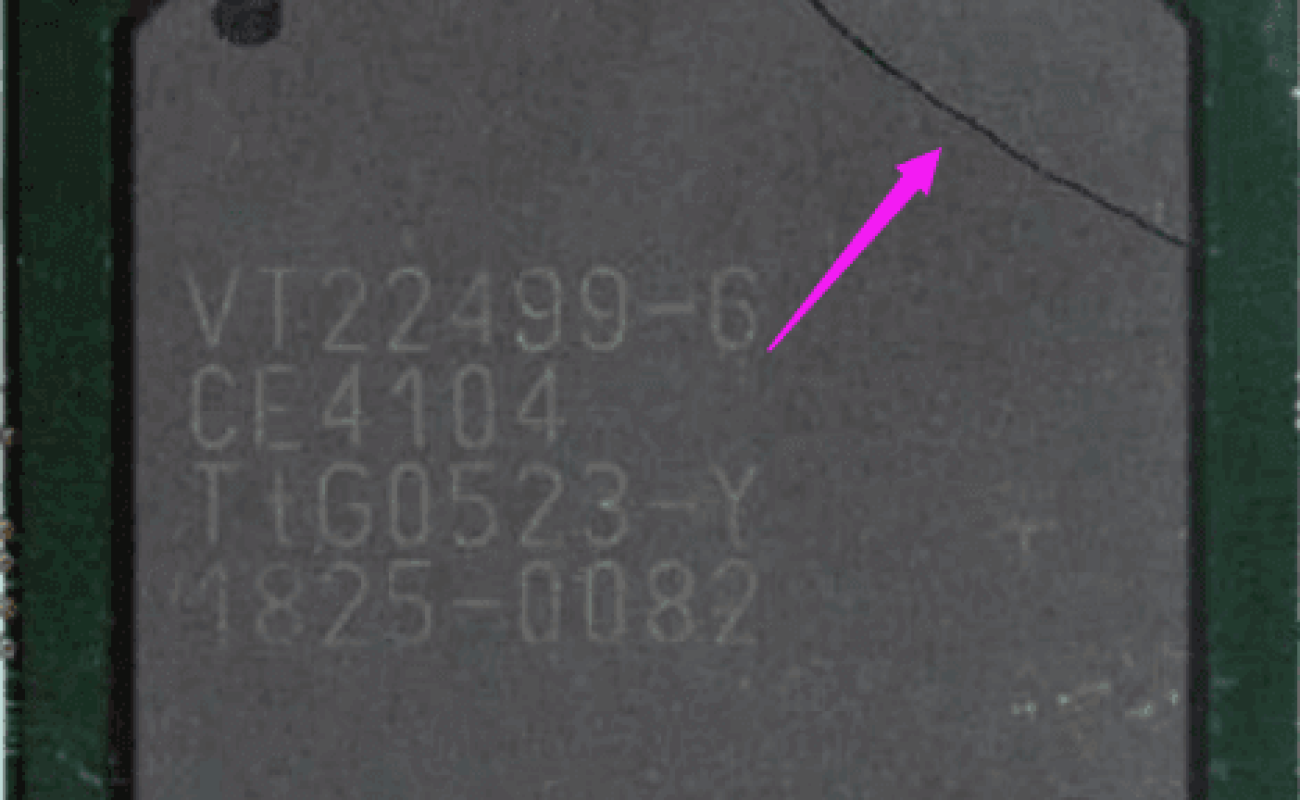

Fragments or cracks can expose the substrate of components or functional materials, or affect sealing, integrity, shape, assembly, or functionality.

Dents and scratches on the main body of the component can affect its form, assembly, and function or exceed the manufacturer's specifications.

Damaged areas with enlarged signs, such as cracks, sharp angles, and hot brittle materials.

Get a Quotation

Your trusted partner and one-stop supplier for FPC/PCB manufacturing, component procurement, FPC/PCB assembly, and electronic manufacturing. With over 16 years of experience, we have been providing high-quality FPC/PCB at competitive prices to over 1000 customers worldwide. Our company has passed ISO9001:2015 certification and UL certification, and all of our products have undergone 100% electronic testing and passed AOI and X-RAY inspections to meet the highest industry standards. Therefore, please obtain an immediate quote from our sales team as we will handle the remaining matters.